Understanding the Advantages of the Best CNC Plasma Table for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, the need for precision and efficiency has led to the rising popularity of CNC plasma tables. According to a report by Market Research Future, the global CNC plasma cutting market is expected to witness a significant growth rate of approximately 5.4% from 2021 to 2027, driven by advancements in technology and increasing demand for high-quality metal fabrication. Investing in the best CNC plasma table can drastically improve productivity while reducing operational costs, making it a fundamental tool for modern manufacturers. This blog post delves into the myriad advantages of using a high-quality CNC plasma table, providing insights on how to select the right system that aligns with your manufacturing needs and enhances overall performance.

The Technology Behind CNC Plasma Tables: A Comprehensive Overview

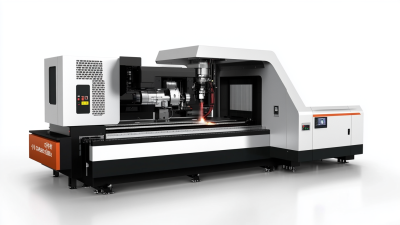

CNC plasma tables have revolutionized the manufacturing landscape, offering precision and efficiency in metal cutting. These tables utilize computer numerical control (CNC) technology to automate the cutting process, which significantly reduces the risk of human error. According to a report by MarketsandMarkets, the CNC plasma cutting machine market is projected to grow from USD 4.30 billion in 2020 to USD 5.83 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth underscores the increasing reliance on automated systems in manufacturing.

When considering a CNC plasma table, it’s essential to understand the technology behind it. These tables use high-temperature plasma to cut through various materials with remarkable speed and accuracy. The system operates by creating an electrical channel of ionized gas, which heats and melts the metal. For optimal performance, ensure that your CNC plasma table is equipped with advanced software that allows for precise design modifications and cutting parameters.

**Tip:** Regular maintenance and calibration of your CNC plasma table can ensure longevity and maintain cutting quality. Also, investing in high-quality consumables, such as electrodes and nozzles, can improve cutting efficiency. **Tip:** Familiarize yourself with the software interface; this can greatly enhance productivity by enabling more complex design capabilities.

Key Factors to Consider When Choosing the Best CNC Plasma Table

When selecting the best CNC plasma table for your manufacturing needs, several key factors should guide your decision. First and foremost, consider the table's size and cutting capacity. Larger tables allow for bigger projects and improved workflow, but it’s essential to ensure that your workspace can accommodate the size of the table you choose. Additionally, take note of the material thickness the plasma table can effectively cut; this varies between models and can significantly influence your production capabilities.

Another critical factor to consider is the software compatibility and technology features. A user-friendly interface paired with powerful CAD/CAM software can enhance your productivity and reduce the learning curve for operators. Look for CNC plasma tables that offer advanced features such as automatic torch height control, which ensures consistent cutting quality and efficiency. Lastly, check the manufacturer’s support and warranty terms. A reliable support system can save you time and money in the long run, providing assistance when you need it most. By carefully evaluating these factors, you can select a CNC plasma table that best meets your manufacturing needs and contributes to your operational success.

Understanding the Advantages of the Best CNC Plasma Table for Your Manufacturing Needs - Key Factors to Consider When Choosing the Best CNC Plasma Table

| Feature | Description | Importance |

|---|---|---|

| Cutting Thickness | The maximum thickness of material that can be effectively cut. | High |

| Table Size | Dimensions of the cutting area available on the plasma table. | Medium |

| Cutting Speed | The speed at which the plasma cutter can operate during cuts. | High |

| Software Compatibility | Support for various CAD/CAM software for design processing. | High |

| Power Source | Type and strength of the power supply used for plasma cutting. | Medium |

| Portability | Ease of transporting the CNC plasma table if needed. | Low |

| Cut Quality | The finish quality of the cut edges produced by the machine. | High |

Benefits of Investing in a High-Quality CNC Plasma Table for Manufacturing

Investing in a high-quality CNC plasma table can significantly enhance your manufacturing operations by providing unmatched precision and efficiency. As industries strive to stay competitive, especially in the face of evolving technology, having an advanced plasma cutting machine becomes crucial. With features like automated control and high-speed cutting, these tables can drastically reduce production time while increasing the accuracy of cuts, leading to less material waste and more streamlined processes.

Moreover, the growing demand for high-precision manufacturing tools highlights the vital role of CNC plasma tables in modern fabrication. Businesses looking to upgrade their equipment, like those faced with outdated machinery, find that a quality CNC plasma table is not just an upgrade but a necessary investment. This shift not only allows for a greater range of applications but also positions companies to take advantage of new market opportunities driven by innovation, underscoring the importance of integrating cutting-edge technologies into their operations.

Understanding the Advantages of the Best CNC Plasma Table

This bar chart illustrates the advantages of investing in a high-quality CNC plasma table for manufacturing, highlighting key benefits such as precision, speed, cost-effectiveness, and versatility.

Comparing Top CNC Plasma Tables: Features, Performance, and Price

When selecting the best CNC plasma table for your manufacturing needs, it's essential to compare various options based on their features, performance, and price. High-quality CNC plasma tables come equipped with advanced technology, such as precision motion control and customizable cutting speeds, which enable manufacturers to achieve intricate designs with remarkable accuracy. Key features to look for include the cutting area size, material compatibility, and software integration, ensuring that the table can handle a diverse range of projects.

Performance is critical when discussing CNC plasma tables, as it directly impacts productivity and output quality. Tables that offer high cutting speeds and exceptional edge quality can significantly reduce production times. Additionally, manufacturers should consider the reliability and durability of the table and its components, such as the plasma torch and torch height control systems, which play a pivotal role in maintaining consistent performance. Finally, price remains a crucial factor, yet balancing cost with quality and features will ultimately yield the best return on investment for businesses in the long run.

Maintenance Tips to Extend the Lifespan of Your CNC Plasma Table

Maintaining your CNC plasma table is crucial for ensuring its longevity and optimal performance. Regular maintenance not only enhances the efficiency of your manufacturing processes but also helps in avoiding costly repairs down the line. One of the most effective tips for extending the lifespan of your CNC plasma table is to implement a consistent cleaning routine. After each use, make sure to remove any metal slag or debris from the cutting surface and the internal components. This practice reduces wear and tear, allowing the machine to operate smoothly and ultimately prolonging its operational life.

Another key aspect of maintenance is monitoring and replacing consumables, such as cutting tips and nozzles, when they begin to show signs of wear. Neglecting to change worn-out parts can lead to decreased cutting performance and inefficiency, which can affect the quality of your finished products. Additionally, regularly checking the gas supply and ensuring proper pressure levels will help maintain optimal cutting conditions and prevent potential damage to the table.

Lastly, it's essential to keep an eye on electrical connections and cables for any signs of wear or damage. Regular inspections can help identify issues early on, preventing significant malfunctions. By adopting these tips, you can ensure that your CNC plasma table remains a reliable asset in your manufacturing toolkit for years to come.

Related Posts

-

Ultimate Guide to Maximizing Efficiency with CNC Plasma Cutting Machines

-

Global Manufacturing Guidelines for Cnc Plasma Cutting Machine Innovations

-

Discover Innovations in Plasma Cutting Technology at the Record-Breaking 137th Canton Fair

-

How to Choose the Best Cnc Plasma Cutting Machine for Your Business Needs

-

What Makes the Best Plasma Machine Stand Out in Precision Cutting Technology

-

Discover Premium Plasma Machines from China Your Global Manufacturing Ally