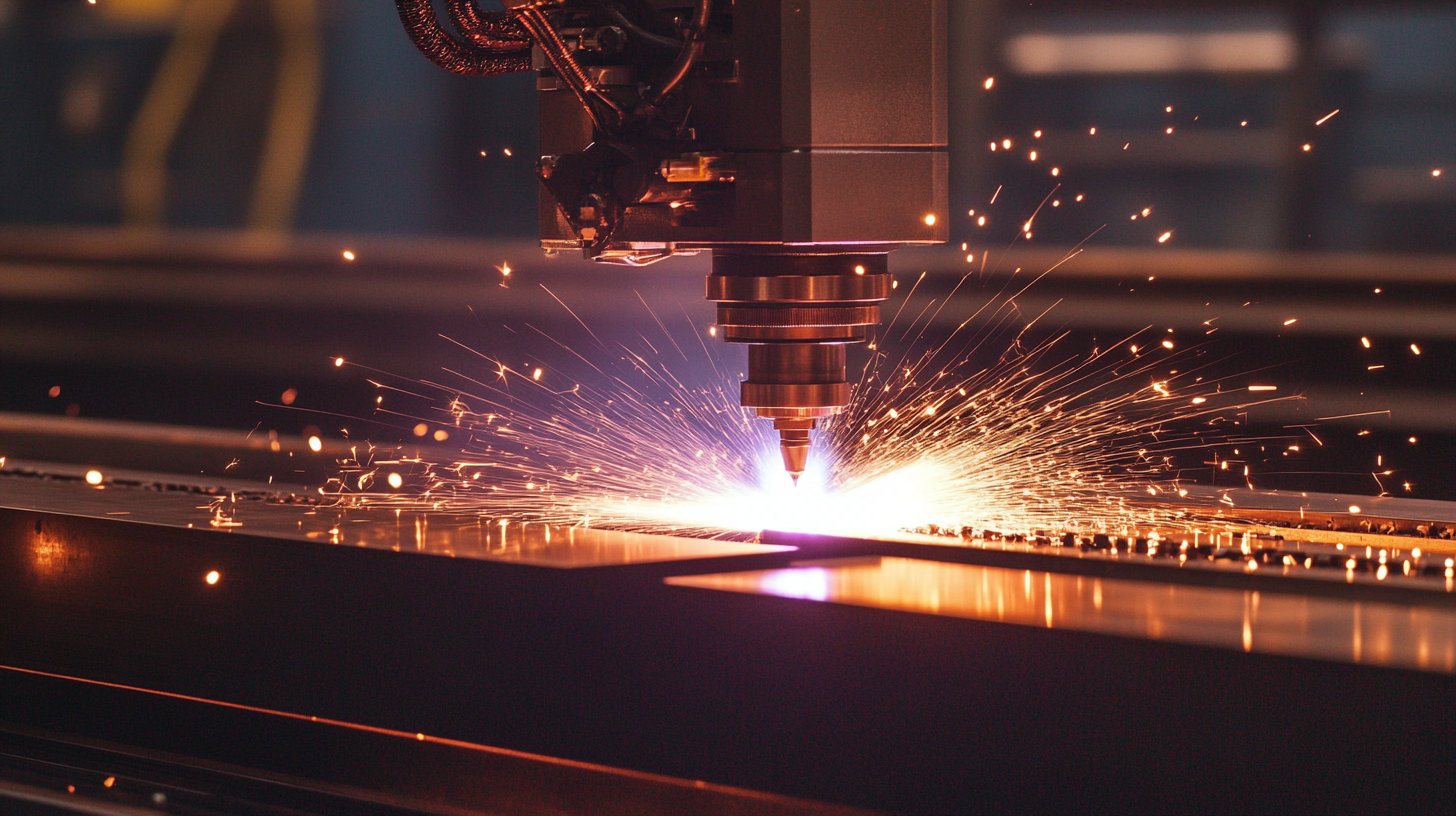

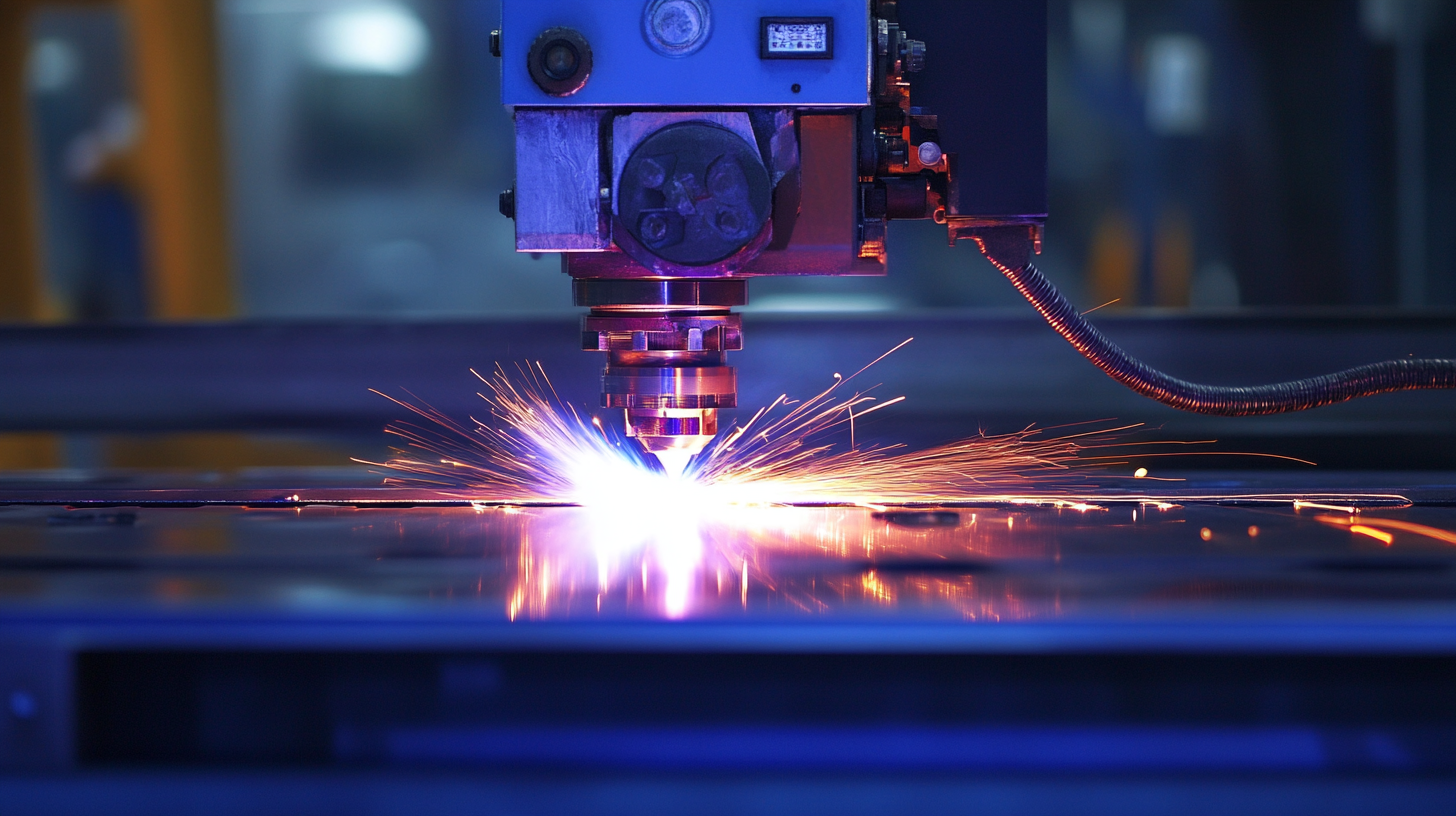

What Makes the Best Plasma Machine Stand Out in Precision Cutting Technology

In today’s rapidly evolving manufacturing landscape, the plasma machine stands out as a vital tool in precision cutting technology. According to a recent report by MarketsandMarkets, the global plasma cutting equipment market is projected to reach $5.07 billion by 2028, growing at a CAGR of 4.9%. This growth underscores the increasing reliance on advanced plasma cutting systems, particularly those manufactured in China, which has become a leading exporter in this field. The unique advantages of plasma machines, including speed, precision, and versatility, have made them indispensable in various industries ranging from automotive to aerospace. As manufacturers seek cost-effective yet high-quality solutions, understanding the key features that differentiate top-performing plasma machines is essential for optimizing production processes and maintaining competitive edge in a dynamic global market.

Key Features That Define Superior Plasma Cutting Machines

When it comes to plasma cutting technology, several key features distinguish superior machines from the rest. One primary aspect is the torch technologies employed in these machines. Advanced torches with enhanced cooling mechanisms allow for longer operational periods and improved cutting quality. Additionally, the precision of the cutting process is greatly affected by the machine’s ability to adapt to various materials and thicknesses, ensuring clean cuts without excessive dross.

Another critical feature includes the control systems that enable precise adjustments during cutting. High-end plasma machines come equipped with user-friendly interfaces and sophisticated software that facilitate real-time monitoring and adjustments. This empowers operators to optimize the settings for different materials, resulting in improved accuracy and efficiency.

Tip: Regularly maintaining your plasma cutting machine is essential to ensure optimal performance. Schedule routine checks on the torch and power supply to prolong the machine’s lifespan and enhance cutting precision.

Moreover, portability and ease of setup are increasingly important for users who need flexibility on the job site. Compact designs that offer easy transportation, combined with intuitive setup instructions, can significantly enhance productivity.

Tip: Choose a plasma machine that balances weight with durability to ensure it can withstand the rigors of transport without compromising on quality cuts.

Industry Applications of Plasma Cutting Technology in Various Sectors

Plasma cutting technology has become an indispensable tool across various industries due to its precision and efficiency. With the global plasma technology market projected to grow from USD 3,452.8 million in 2024 to a significant increase by 2030, sectors ranging from automotive to aerospace increasingly leverage this technology. The capability to cut through thick materials with minimal distortion makes plasma cutting ideal for fabricating complex shapes in metal manufacturing.

Moreover, the CNC cutting machines market is also witnessing robust growth, expected to reach USD 11,671.4 billion by 2032. This surge emphasizes the rising demand for automation in the fabrication process, allowing manufacturers to enhance production efficiency. Industries such as construction and shipbuilding benefit from the accuracy of plasma machines, which helps in reducing operational costs while maintaining high-quality standards. As these technologies continue to evolve, we can anticipate even broader applications and innovations in the manufacturing landscape.

How to Choose the Right Plasma Machine for Your Precision Cutting Needs

When selecting the right plasma machine for your precision cutting needs, it’s essential to consider several key factors. First, assess the machine’s cutting capacity. Ensure that it can handle the types of materials and thicknesses you commonly work with. Machines vary significantly in their cutting abilities, so knowing your requirements will help you make an informed decision.

Another crucial aspect is the level of automation. For businesses aiming for increased efficiency, choosing a plasma machine with advanced automation features can greatly enhance productivity. These machines often come equipped with software that optimizes cutting paths and minimizes waste, which can significantly impact your overall operational costs.

Tips: Always prioritize the machine’s ease of use and maintenance. A user-friendly interface can save training time and reduce operational errors. Additionally, consider the availability of customer support and spare parts for your selected machine, as reliable service can prevent costly downtimes and ensure longevity. Investing time in researching different models will pay off in the long run, ensuring you choose the best plasma machine tailored to your specific precision cutting needs.

Real-World Success Stories: Plasma Cutting Transformations Across Industries

Plasma cutting technology has revolutionized various industries by providing precision and efficiency that are unmatched by traditional cutting methods. Real-world success stories abound, showcasing how companies have embraced plasma cutting to enhance productivity and reduce costs. For instance, a fabrication shop that switched to plasma cutting reported a 30% decrease in material waste and a significant reduction in processing time, leading to accelerated project completion.

Tip: When considering integrating plasma cutting technology into your operations, evaluate your specific needs and the materials you'll be working with. This ensures you choose the right machine that offers the precision and speed required for your projects.

In the automotive industry, plasma cutting has been instrumental in creating intricate component parts with exceptional accuracy. A manufacturer that adopted a high-quality plasma machine was able to streamline their assembly line, ultimately improving turnaround times for new vehicle models. This transformation not only increased their market competitiveness but also enhanced product quality.

Tip: Regular maintenance of your plasma cutting equipment is crucial. Ensure that you schedule routine checks and maintain consumables such as nozzles and electrodes to avoid downtime and guarantee optimal performance.

Tips for Optimizing Performance and Longevity of Plasma Machines

Optimizing the performance and longevity of plasma machines is paramount for achieving excellence in precision cutting technology. One of the key aspects is maintaining stable plasma conditions, which, much like in the recent advancements in nuclear fusion, can significantly enhance productivity. By employing advanced monitoring systems that utilize AI and machine learning, operators can continuously fine-tune the plasma parameters. This ensures that the cutting edges are maintained at optimal temperatures and pressures, minimizing wear and extending the lifespan of the cutting equipment.

Incorporating high-density plasma generation techniques can also contribute to better performance. Just as the recent discoveries in fusion technology highlight the importance of creating stable environments for plasma, plasma cutting machines can benefit from controlled conditions that prevent disruptions in the energy flow. Regular maintenance checks and software updates further enhance the efficiency and longevity of these machines. By adopting a proactive approach to machine care and employing cutting-edge technologies, manufacturers can ensure consistent quality and durability in their plasma cutting applications.