China Engineered Best Plasma Machines for Global Excellence and Trusted Quality

In the rapidly evolving landscape of manufacturing technology, Plasma Machines have emerged as a cornerstone for precision and efficiency. As industries worldwide strive for excellence and reliability, China's innovative engineering has set a remarkable standard in the production of advanced Plasma Machines. This blog will delve into a comparative analysis of various Plasma Machines, highlighting their unique features, applications, and the trusted quality that Chinese manufacturers are renowned for. By examining these technologies, we aim to provide insights into how these machines not only enhance operational capabilities but also establish a benchmark for global excellence. Join us as we explore the pivotal role that Plasma Machines play in driving industrial advancements across the globe.

Key Features of China's Plasma Machines: Innovation Meets Performance

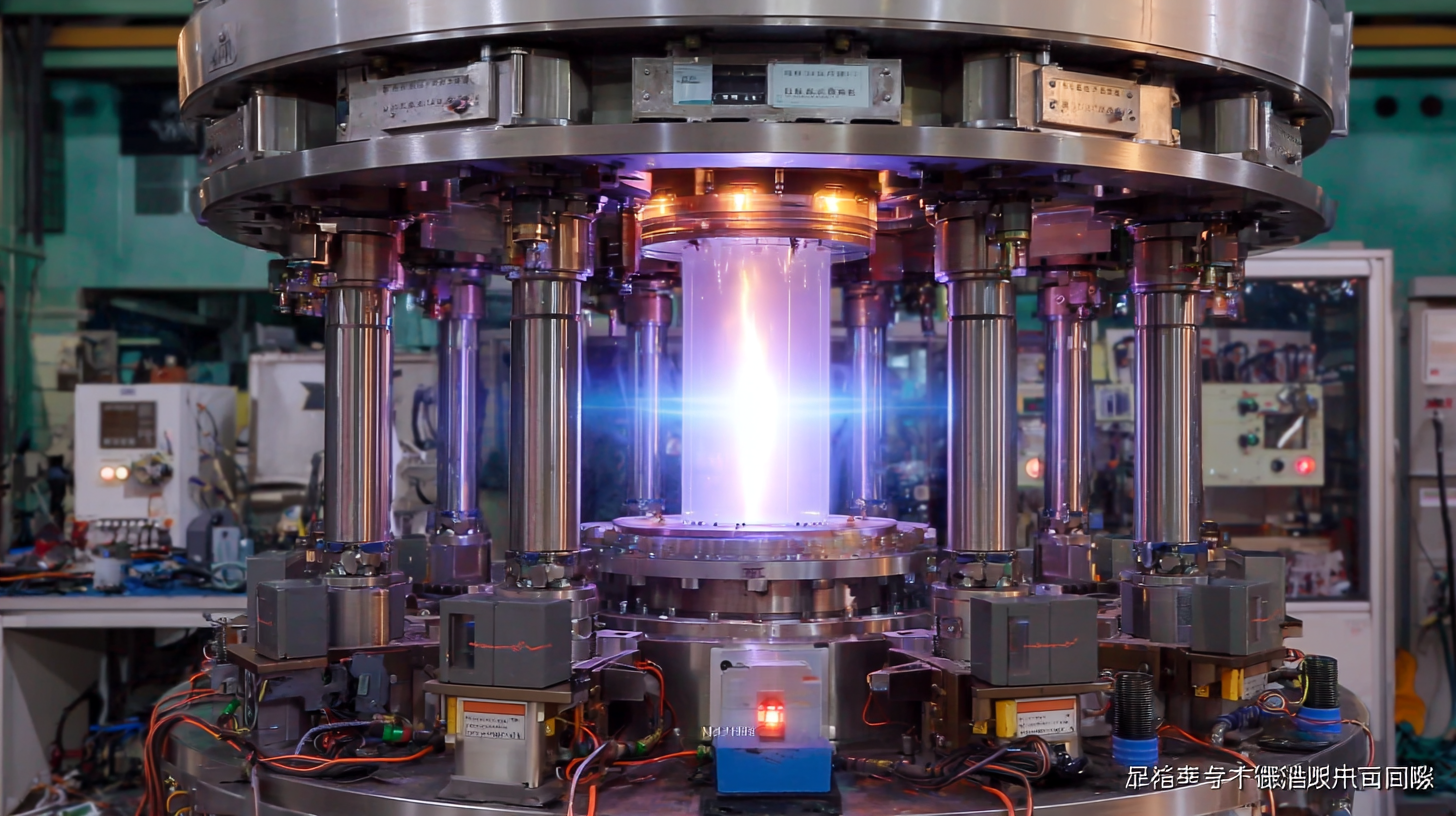

China’s plasma machinery has garnered significant attention in recent years, merging innovative technology with robust performance. Recent market reports indicate that the Spark Plasma Sintering Equipment market is poised to grow at a remarkable CAGR of 8% until 2025, fueled by the increasing demand for advanced materials and automation. This trend highlights China’s commitment to advancing its manufacturing capabilities in high-tech industries, positioning itself as a key player on the global stage.

Additionally, the Oxygen Plasma Degumming Machine market is projected to surge from USD 120 million in 2024 to an impressive USD 250 million by 2033. This growth illustrates the rising need for efficient plasma technologies across various sectors, reflecting China's strength in research and development. With initiatives such as the development of nuclear fusion technologies, including milestones achieved by its experimental reactors, China is not only enhancing its plasma technology offerings but also contributing to the global shift toward sustainable energy solutions. Through innovation and performance excellence, China continues to elevate the standard for plasma machinery, setting a new benchmark in the industry.

Comparative Analysis: Chinese Plasma Machines vs. Global Competitors

When it comes to plasma machines, China has emerged as a formidable player in the global market, blending advanced technology with cost-effective production. A comparative analysis reveals that Chinese plasma machines often excel in features that enhance efficiency and versatility, making them suitable for a wide array of industrial applications. With innovation at the forefront, manufacturers in China focus on integrating automation and smart technology into their machines, setting a benchmark for performance that rivals well-established international brands.

Contrasting with global competitors, Chinese plasma machines typically offer a more attractive price-to-performance ratio. This is particularly appealing for small to medium-sized enterprises that seek high-quality solutions without the burden of significant investment. While concerns around durability and post-purchase support have been raised, many Chinese manufacturers are addressing these issues by enhancing their service networks and providing comprehensive warranties. As the technology continues to evolve, it is clear that the competitive landscape for plasma machines is shifting, with Chinese companies poised to take a leading role in shaping the future of this industry.

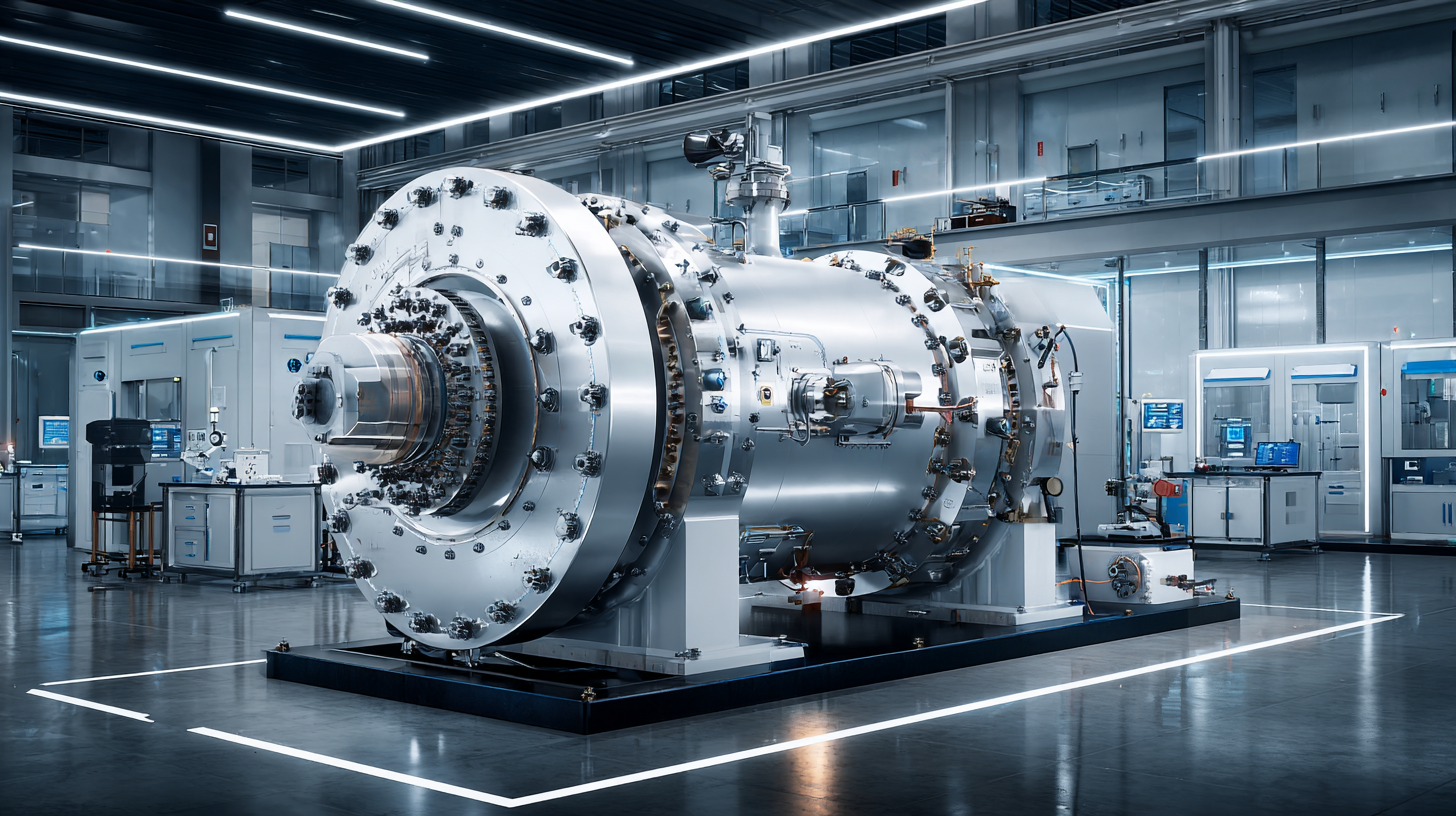

Understanding the Advanced Technology Behind Plasma Cutting

The continuous evolution of plasma cutting technology is fueling innovation across various industries, significantly enhancing manufacturing efficiency and quality. As the global market for plasma cutting machines is projected to grow from $646.2 million in 2023 to $841.4 million by 2030, the focus on advanced plasma technologies has never been sharper. This surge is not just a reflection of demand; it is an acknowledgment of the pivotal role that next-generation plasma solutions play in precision cutting processes.

Among the advancements, cold plasma technology is gaining traction, offering unique advantages in multiple sectors. With its ability to operate at lower temperatures while still achieving high-quality cuts, cold plasma is set to revolutionize traditional cutting methods. New high-performance plasma cutting machines are emerging, showcasing capabilities for medium and heavy thickness plate cutting, thereby pushing the boundaries of what was previously possible in material processing. This technological leap is essential for manufacturers aiming for operational efficiency and competitive advantage in a rapidly evolving market.

Quality Assurance: Testing and Certification Standards for Plasma Machines

In today's competitive landscape, the significance of rigorous testing and certification standards for plasma machines cannot be overstated. China has emerged as a leader in engineering high-quality plasma machines, ensuring that these tools not only meet but exceed global expectations. These machines undergo extensive quality assurance processes, which involve a series of testing protocols designed to assess performance, reliability, and safety. By adhering to international certification standards, manufacturers in China demonstrate their commitment to producing equipment that operators can trust.

Tips for Ensuring Quality in Plasma Machines: Always check for compliance with recognized certification standards such as ISO or CE before purchasing. Additionally, look for manufacturers who provide detailed testing reports and warranty information. This transparency not only builds trust but also assures consumers of the machine's longevity and effectiveness.

Furthermore, continuous innovation plays a critical role in maintaining the quality of plasma machines. Manufacturers should invest in research and development to stay ahead of technological advancements, ensuring that their machines incorporate the latest features and safety measures. Engaging with industry feedback can significantly enhance product performance and user satisfaction.

China Engineered Best Plasma Machines for Global Excellence and Trusted Quality - Quality Assurance: Testing and Certification Standards for Plasma Machines

| Machine Model | Output Power (kW) | Max Cutting Thickness (mm) | Certification Standards | Testing Methodology | Warranty Period (Years) |

|---|---|---|---|---|---|

| Model A300 | 10 | 25 | ISO 9011, CE | Dynamic Testing, Load Testing | 3 |

| Model B500 | 15 | 30 | ISO 13485, ROHS | Performance Testing, Safety Testing | 4 |

| Model C700 | 20 | 35 | ISO 14001, EMC | Endurance Testing, Compliance Testing | 5 |

| Model D900 | 25 | 40 | ISO 27001, CSA | Environmental Testing, Quality Assurance | 6 |

Applications of High-Quality Plasma Machines in Various Industries

The global plasma surface treatment equipment market is set to witness significant growth, projected to increase from $394 million in 2025 to $576.8 million by 2032, with a compound annual growth rate (CAGR) of 5.6%. This expanding market highlights the versatility and importance of high-quality plasma machines across various industries. Applications range from semiconductor manufacturing to advanced materials processing, enhancing surface properties such as adhesion, wettability, and cleanliness.

In recent years, China has emerged as a key player in the development of advanced plasma technology. Companies are rapidly innovating solutions that leverage plasma machines for surface treatment applications. These machines not only improve manufacturing efficiency but also play a crucial role in meeting stringent quality standards. The acceleration in the production capabilities of plasma equipment signifies a strategic investment in technology that responds to global industry needs, ensuring that manufacturers can achieve excellence without compromising on trusted quality.