How to Choose the Best Die Casting Molds for Your Project?

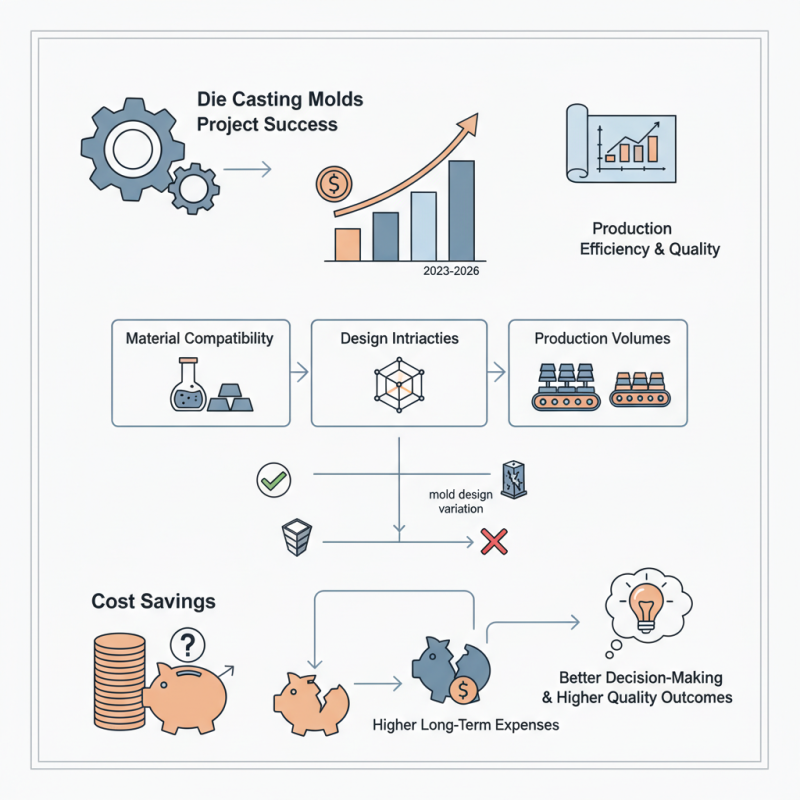

Choosing the best Die Casting Molds is crucial for your project’s success. The die casting industry is projected to reach a market value of $104 billion by 2026. This growth underscores the importance of selecting the right molds. A well-designed mold can enhance production efficiency and improve product quality.

However, the selection process is often complex. Many factors need consideration, including material compatibility, design intricacies, and production volumes. Additionally, slight variations in mold design can significantly impact the performance and durability of the final product. Realizing this complexity can lead to better decision-making and higher quality outcomes.

Indeed, the right Die Casting Molds can lead to substantial cost savings. Yet, companies sometimes overlook key aspects due to budget constraints. This shortsightedness can result in higher long-term expenses. Reflecting on these choices is essential for businesses aiming for success in the competitive die casting landscape.

Understanding Die Casting Molds: Key Concepts and Materials

When selecting die casting molds, understanding materials is crucial. These molds can be made from various metals, typically aluminum or zinc. Aluminum molds are known for their thermal properties and durability. Zinc molds, meanwhile, are often less expensive and easier to work with. Each material has its strengths and weaknesses.

Mold design also plays a significant role. Complex designs may require more intricate molds. Simpler designs can be produced more quickly. However, overly simplistic designs might not meet functional requirements. Designers must balance functionality and manufacturability. It's common to encounter design challenges during this stage. Practical iterations often lead to better outcomes.

Consider the intended production volume. High-volume runs may warrant investing in stronger materials. Lower volumes might allow for less robust options. Each decision impacts the project’s cost and performance. Reflecting on the project needs is essential. Choosing the right mold isn't merely technical; it's also an evolving process that requires flexibility and creativity.

How to Choose the Best Die Casting Molds for Your Project? - Understanding Die Casting Molds: Key Concepts and Materials

| Mold Material | Thermal Conductivity (W/m·K) | Durability (Cycles) | Cost ($/kg) | Recommended Applications |

|---|---|---|---|---|

| Aluminum | 205 | 10,000 | 5 | Automotive, Electronics |

| Magnesium | 156 | 8,000 | 4 | Aerospace, Consumer Products |

| Zinc | 112 | 25,000 | 3 | Hardware, Automotive |

| Copper | 400 | 1,500 | 10 | Electronics, High-Precision Components |

| Steel | 50 | 50,000 | 7 | Heavy Machinery, Industrial Use |

Evaluating Project Requirements: Size, Shape, and Volume Considerations

When evaluating project requirements for die casting molds, size is a critical factor. Measure the dimensions of the parts you want to produce. Consider the largest and smallest pieces. This helps ensure that the mold can accommodate the full range of your designs. Keep in mind that larger molds often require more complex designs and may increase costs.

Shape also plays a significant role in mold selection. Intricate designs can complicate the mold-making process. Think about the angles and curves of your components. Simple shapes are easier to cast but may not meet design needs. Balancing complexity and functionality is vital for success.

Volume considerations are crucial too. Anticipate how many pieces you need. High volume may necessitate durable molds that can withstand repeated use. Conversely, if your project involves small batches, you might focus on cost-effective options. Always reflect on your production goals. Each choice impacts quality, cost, and timeline. Proper planning at this stage saves setbacks later.

Types of Die Casting Molds: Choose the Right Type for Your Application

When selecting die casting molds, understand the different types available. The most common options include sand molds, permanent molds, and investment molds. Each serves unique purposes. Sand molds work well for prototypes due to their flexibility. Permanent molds offer durability and consistent quality for mass production. Investment molds allow for intricate designs and smooth surfaces.

Tip: Assess your project needs before making a choice. Consider manufacturing volume and design complexity. If you expect high-volume orders, permanent molds may be ideal. For limited runs, sand molds can save costs.

Details matter. The choice of mold material can affect lifespan and outcomes. Metal molds are sturdy but can be expensive. Plastic molds are less durable but cost-effective for small batches. Pay attention to cooling systems as well; they impact cycle times drastically.

Tip: Review product specifications. Understand the mold design and its implications on the final product. Reflect on how ease of use and maintenance also affects project timelines. Aim for molds that balance durability with your production needs.

Cost Analysis: Balancing Quality and Budget for Mold Selection

Choosing the right die casting molds can significantly impact your project's success. One critical aspect is the cost analysis involved in selecting these molds. Striking a balance between quality and budget is essential. Quality molds can enhance production efficiency and reduce defects. However, they often come at a higher price. Understanding your project's specific needs is key.

Tips: Always consider the lifespan of the mold. A higher upfront cost might save you money in the long run if the mold lasts longer. Additionally, explore various materials. Some may offer durability at a lower price.

Be aware that the cheapest option isn't always the best. It may lead to frequent replacements or repairs. Factor in maintenance costs when assessing mold options. Ensure you have a budget but prepare for potential overruns. If you compromise too much on quality, it may lead to unforeseen expenses later. Respect the balance between initial cost and potential output quality. It’s a fine line to walk.

Working with Manufacturers: Best Practices for Collaborating on Molds

When working with manufacturers for die casting molds, communication is key. Clearly outline your project requirements. Be specific about dimensions, materials, and timelines. This can help avoid misunderstandings. It's important to listen to their feedback. They have experience that can improve your design.

Building a strong relationship with your manufacturer is essential. Regular check-ins can prevent delays. Share updates and be open to suggestions. Sometimes, a change in design may lead to better outcomes. Don't hesitate to ask questions. Ensure that both parties are aligned on expectations.

Mistakes can happen in any project. You might overlook certain details or misinterpret the manufacturer's feedback. Reflecting on these experiences can lead to better collaboration in the future. Learn from past errors, and don't repeat them. In the end, open dialogue and mutual respect can pave the way for a successful partnership.