Ultimate Guide to Choosing the Best Cnc Table for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, selecting the right CNC table is pivotal for optimizing production efficiency and ensuring high-quality output. According to a report by the International Federation of Robotics, the global demand for CNC machinery has risen dramatically, with a projected growth rate of 8% annually through 2026. This surge underscores the necessity of understanding the various types and specifications of CNC tables available in the market. Properly chosen CNC tables not only enhance precision and reduce waste but also align with industry standards, thereby addressing common production problems such as machine downtime and operational inefficiencies. As manufacturers strive to keep pace with technological advances and increasing competition, investing in the right CNC table becomes essential for meeting diverse manufacturing needs and achieving long-term success.

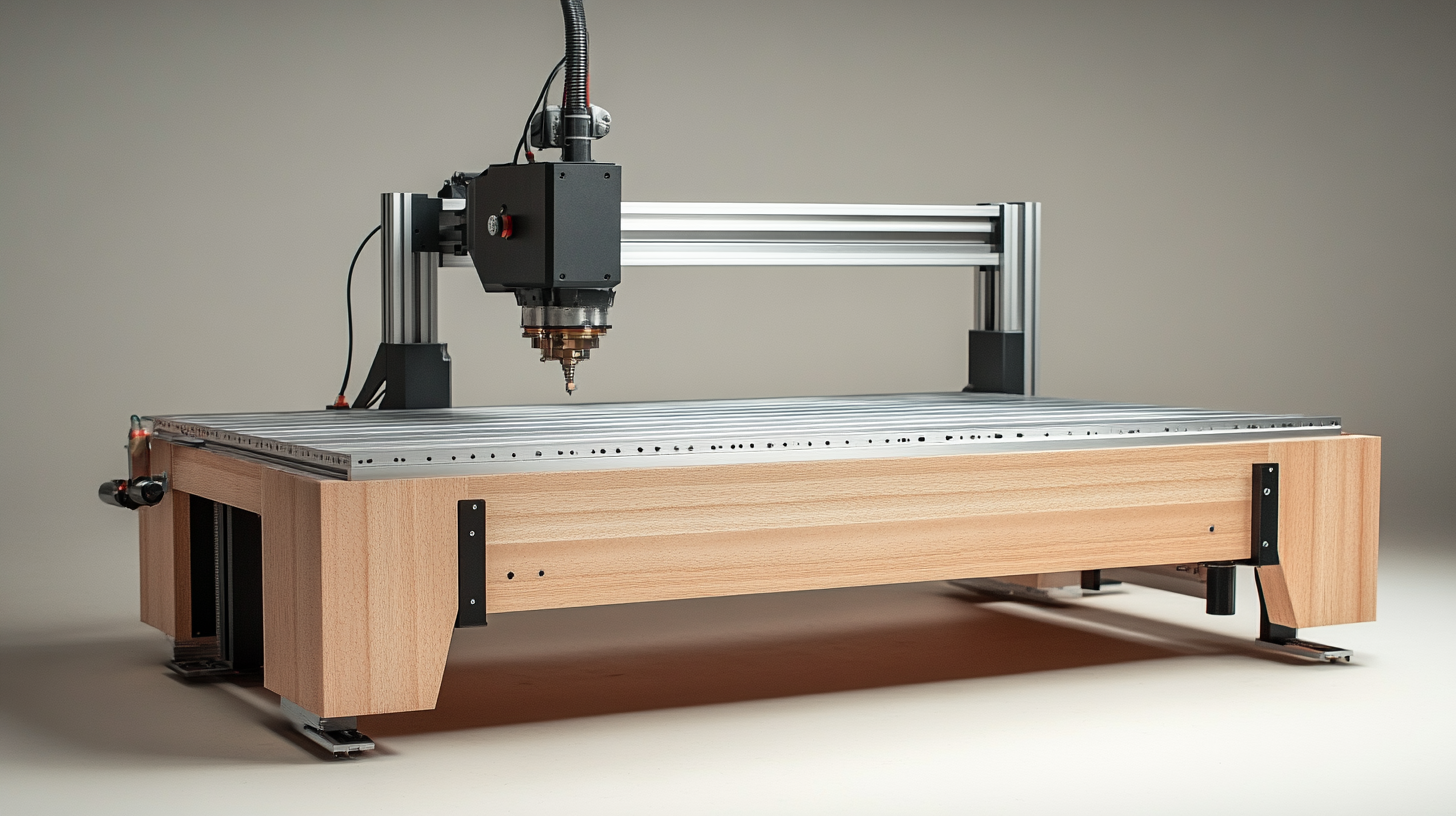

Understanding CNC Tables: An Overview of Types and Applications

When choosing the right CNC table for your manufacturing needs, it's essential to understand the various types and their applications. CNC tables are available in various configurations, including plasma cutting machines, which have gained significant traction in recent years. The CNC plasma cutting machines market, valued at approximately USD 673.2 million in 2024, is projected to grow at a CAGR of over 5.1% from 2025 to 2034. This growth is driven by the increasing demand from industries requiring precise and efficient cutting solutions.

Tips: Consider your specific applications when selecting a CNC table. For instance, if you focus on high-precision tasks, investing in a larger CNC milling machine may be beneficial to handle complex aerospace components.

Additionally, keep an eye on the CNC machine monitoring software market, which is expected to offer valuable insights into operational efficiency and production optimization. This growing market emphasizes the importance of integrating technology into your CNC workflow for better performance and reliability.

By understanding the types and applications of CNC tables, and leveraging data-driven insights, you can make informed decisions that align with your manufacturing goals.

Evaluating Material Compatibility for Your CNC Table Selection

When selecting a CNC table, evaluating material compatibility is paramount to ensure optimal performance and efficiency in your manufacturing processes. Different materials have unique properties that can affect the machining process, including strength, hardness, and thermal conductivity. It's essential to align your CNC table choice with the materials you intend to work with, whether it's metal, wood, or composite materials. Each material may require specific table designs or surface treatments to improve adhesion and stability during machining.

Tip: Always consider the weight and size of the materials you plan to use. Heavier materials may necessitate a sturdier table for enhanced stability, while lighter materials might benefit from a more versatile, adjustable table design.

Moreover, the type of cutting tools and machining techniques you are employing can dictate the compatibility of your chosen CNC table with specific materials. For instance, if you are working with softer materials like plastics or wood, a CNC table with a vacuum hold-down system could prove advantageous.

Tip: Consult the manufacturer’s guidelines for your CNC equipment and tools, as they often provide insights into the best material pairings for optimal results. This consideration can lead to improved cutting speeds, precision, and overall satisfaction with your CNC table choice.

Cost-Effectiveness of Different CNC Table Alternatives in Manufacturing

When considering the cost-effectiveness of CNC tables for manufacturing, it's essential to evaluate the various alternatives available in the market. Traditional CNC tables often come with a hefty price tag, making initial investments daunting for small to medium-sized enterprises. However, emerging solutions such as plasma cutting machines offer a viable alternative, striking a balance between performance and affordability. These machines not only reduce upfront costs but also lower operational expenses, thereby enhancing the overall return on investment.

Moreover, the choice of a CNC table also impacts production efficiency and quality. For businesses focused on sustainability, newer technologies like plasma-based solutions can provide eco-friendly benefits while maintaining precision. The integration of life cycle assessments into purchasing decisions ensures that manufacturers can not only meet operational needs but also align with environmental goals.

By weighing the total cost of ownership against the productivity gains offered by different CNC options, manufacturers can make informed decisions that enhance both profitability and sustainability in their operations.

Comparative Analysis of Fixed vs. Adjustable CNC Tables

When choosing a CNC table for manufacturing needs, understanding the differences between fixed and adjustable models is critical. Fixed CNC tables, as per a 2021 study by the National Association of Manufacturers, offer stability and precision, making them ideal for high-volume production where consistency is key. These tables maintain a rigid framework, which reduces vibrations and enhances the accuracy of the machining process. Reportedly, companies using fixed CNC tables have witnessed a 15% increase in production efficiency due to their stability during long runs.

Conversely, adjustable CNC tables provide flexibility for various machining operations. A report from the Association for Manufacturing Technology emphasizes the growing demand for adjustable tables, which cater to diverse workpieces and allow manufacturers to easily switch between jobs. This adaptability can lead to shorter setup times, improving overall workflow efficiency. In fact, businesses that utilize adjustable CNC tables often report a 20-30% decrease in lead times, enabling them to respond swiftly to market demands. Thus, while both table types have unique advantages, the decision largely hinges on specific manufacturing requirements and expected production volume.

Comparative Analysis of Fixed vs. Adjustable CNC Tables

This chart illustrates the performance comparison between Fixed CNC Tables and Adjustable CNC Tables based on various manufacturing needs. The data points represent common use cases and efficiency metrics.

Industry Trends: Future Innovations in CNC Table Technology

As we look ahead to the future of CNC table technology, the industry is poised for remarkable innovations that promise to enhance efficiency and precision in manufacturing. One trend gaining momentum is the integration of artificial intelligence in CNC systems. These smart machines can analyze data in real-time, optimizing processes and reducing downtime. With AI, manufacturers can expect fewer errors, improved product quality, and a faster turnaround time.

When selecting a CNC table, consider investing in models that align with these technological advancements. Look for features such as automated calibration systems and adaptive controls, which will keep you ahead of the competition. Additionally, keep an eye on hybrid machines that combine traditional CNC methods with 3D printing capabilities. This hybrid approach allows for greater design flexibility and can significantly shorten production cycles.

Tip: Always evaluate the scalability of a CNC table. As your manufacturing needs grow or change, having a flexible machine ensures that you can adapt without investing in new equipment. Moreover, staying updated on industry trends can help you make informed decisions that align with future requirements.