Challenges When Choosing the Right Best Cnc Plasma Table for Your Business Needs

When it comes to elevating your business's manufacturing capabilities, choosing the best CNC plasma table is a critical step that can significantly impact your operations. The right CNC plasma table not only enhances precision and efficiency but also allows for greater versatility in handling various projects. However, selecting the best CNC plasma table can be fraught with challenges that vary depending on your unique business needs, budget constraints, and technical requirements. Understanding these challenges will help you make an informed decision, ensuring that your investment leads to enhanced productivity and profitability.

Moreover, the market is flooded with different options, each boasting unique features that can complicate the selection process. From varying sizes and cutting capabilities to the differences in software compatibility and after-sales support, potential buyers must navigate a labyrinth of choices. This blog will delve into the key challenges you may encounter when searching for the best CNC plasma table, providing insights and expert recommendations to help you choose wisely for your business's future.

Understanding the Different Types of CNC Plasma Tables Available

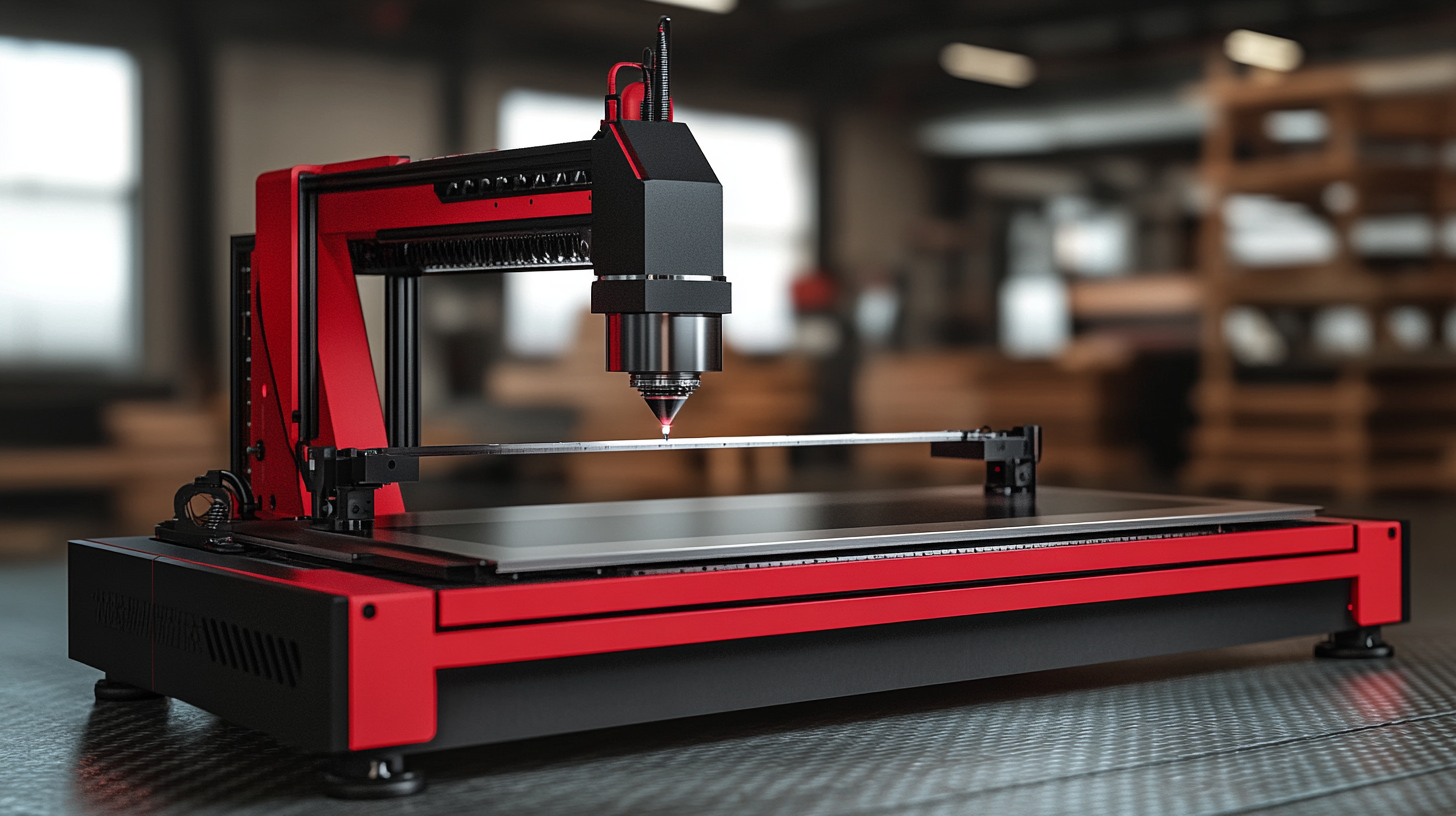

When considering the right CNC plasma table for your business, it's essential to understand the different types available in the market. There are primarily two categories: manual/handheld and CNC/automated plasma cutting machines. Manual systems are typically more economical and suited for small, less complex tasks, while CNC systems offer greater precision and are ideal for high-volume, intricate projects. According to industry reports, the CNC plasma cutting machine market is projected to grow significantly, driven by advancements in technology and increasing demand for automation across various sectors.

The versatility of CNC plasma tables can be distinguished further by their application, which ranges from industrial fabrication to artistic uses. For instance, in the metalworking industry, CNC plasma tables are favored for their ability to cut through various materials with high accuracy and rapid speed. A recent analysis indicates that the demand for CNC machines is being fueled by the need for efficiency in manufacturing processes, wherein investments in automated machinery are being prioritized.

Moreover, businesses must also consider budget constraints alongside the quality and features of the equipment. While advanced CNC plasma tables can be an investment, the return in terms of productivity and reduced labor costs can be substantial in the long run. As the market evolves, it is crucial to stay updated on trends and technological advancements to make informed decisions that align with specific business needs.

Key Features to Consider for Your Business Requirements

When selecting the right CNC plasma table for your business, it’s crucial to focus on key features that will align with your operational needs. The first consideration should be the size and material capabilities of the CNC plasma table. Depending on the types of projects you intend to undertake, you may require a machine that accommodates larger dimensions or diverse material types such as steel, aluminum, or even copper.

Another essential feature to analyze is the software compatibility and interface. Advanced CNC plasma tables should offer user-friendly software that integrates smoothly with your design tools. This not only enhances productivity but also reduces the learning curve for operators, facilitating a quicker return on your investment.

Furthermore, consider the table's precision and speed. In sectors where efficiency and accuracy are paramount, investing in a plasma table with high cutting speed and exceptional cutting quality will have a significant impact on your output and overall business success. It's also wise to evaluate the machine's support and warranty options, ensuring you have a safety net in case of technical issues that might arise during operations. By prioritizing these features, your business can establish a solid foundation for future growth and productivity enhancements.

Budgeting for a CNC Plasma Table: Costs and Long-term Investments

When it comes to selecting a CNC plasma table for your business, budgeting is a crucial factor that cannot be overlooked. The initial cost of a CNC plasma table can vary significantly based on its size, features, and capabilities. It's essential for businesses to determine their budget not just for the purchase but also for maintenance and operation in the long run. A high-quality table might come with a heftier price tag, but it can lead to greater efficiency and fewer repairs down the line, ultimately making it a sound investment.

In addition to upfront costs, businesses should also consider the long-term implications of their purchase. Discussing operational costs such as electricity, consumables like plasma cutting tips and gases, and routine maintenance is vital. These expenses can add up quickly, potentially impacting your overall budget. Investing in reliable equipment may require a larger initial budget, but it often means lower operational costs and less downtime. By carefully evaluating these long-term financial commitments, businesses can make informed decisions that align with their growth goals and operational needs.

Evaluating Manufacturer Reputation and Support Services

When choosing the best CNC plasma table for your business, evaluating manufacturer reputation and support services is crucial. According to a recent study featured in the Performance Analytics Benchmarking report, companies with strong reputations typically show around a 25% higher customer satisfaction rate. This correlation highlights the importance of not only selecting a quality machine but also partnering with a manufacturer that can provide robust support and service.

Supplier identification and evaluation services play a key role in unearthing reliable manufacturers. Firms that take the time to assess their suppliers often save significant amounts of time and money in the long run. A report from RealPage indicates that integrating Online Reputation Assessment (ORA™) scores can help businesses precisely gauge a supplier's market standing and customer feedback. By applying these scores in your evaluation, you can ensure that you're working with a manufacturer whose quality and service meet your needs.

Furthermore, understanding a company's commitment to sustainability and innovation can affect your purchasing decision. The Climate Transition Assessment (CTA) provides insights into a company's trajectory regarding climate initiatives. Manufacturers actively engaging in sustainable practices not only enhance their reputation but also contribute positively to the industry's ecological footprint. As businesses increasingly lean toward environmental responsibility, selecting a CNC plasma table manufacturer that prioritizes these values could give you a competitive edge.

Common Pitfalls to Avoid When Purchasing a CNC Plasma Table

When purchasing a CNC plasma table, navigating common pitfalls is essential to ensure you make an informed decision that aligns with your business needs. One prevalent mistake is underestimating the importance of table size and capacity. According to a report by the Fabricators and Manufacturers Association, nearly 30% of businesses that faced production delays in the last fiscal year cited equipment size limitations as a primary issue. A thorough assessment of your projects' dimensions will help you choose a table that not only accommodates current tasks but also future expansions.

Another significant oversight is neglecting the importance of software compatibility. A comprehensive study from the Technical Education Research Association revealed that about 25% of CNC plasma table buyers encountered workflow disruptions due to software incompatibility. Ensuring that your chosen CNC plasma table works seamlessly with design and production software is crucial for maximizing productivity. Investing in a system that integrates well with existing technologies can save significant time and reduce operational hiccups, boosting overall efficiency.

Additionally, many buyers overlook the impact of ongoing maintenance and support services when selecting a CNC plasma table. A survey conducted by the National Welding and Fabrication Association indicated that over 40% of machinery breakdowns could be attributed to insufficient maintenance support. Identifying a supplier who offers robust post-purchase service, including timely support and access to replacement parts, can significantly mitigate downtime and enhance the longevity of your equipment, ultimately protecting your investment.