Innovative Applications of Cnc Plasma Cutting Machine in Various Industries

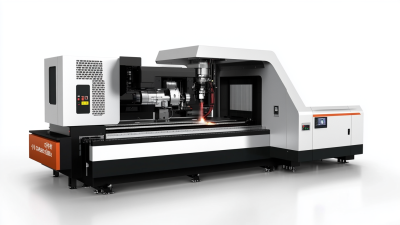

The utilization of the CNC Plasma Cutting Machine has revolutionized the manufacturing landscape across various industries, showcasing its immense versatility and efficiency. According to a report by MarketsandMarkets, the global CNC machine market is projected to reach $117.23 billion by 2026, with plasma cutting technologies playing a pivotal role in this growth. The precision and speed offered by CNC plasma cutting make it an ideal choice for metal fabrication, automotive, aerospace, and construction sectors, where demands for accuracy and minimized waste are paramount.

As industries continue to seek innovative solutions to enhance productivity and reduce costs, the adoption of CNC Plasma Cutting Machines is increasingly recognized as a critical investment. This blog will explore the innovative applications of these machines, highlighting their transformative impact and the future potential they hold in various industrial settings.

Revolutionizing Metal Fabrication: CNC Plasma Cutting in Manufacturing

CNC plasma cutting technology is fundamentally transforming the landscape of metal fabrication in manufacturing. With its capability to deliver high precision and efficiency, this method is being embraced across various sectors, from automotive to aerospace. As the global plasma cutting machine market is projected to expand significantly, from $699.5 million in 2025 to $905.2 million by 2032, the impact of this technology is becoming increasingly evident. Manufacturers are leveraging CNC plasma systems to enhance productivity, reduce material wastage, and increase the quality of finished products.

The use of CNC plasma cutting in industries like aerospace presents unique advantages, especially when dealing with advanced materials such as nickel superalloys. These alloys, known for their exceptional strength and resistance to high temperatures, are essential for aerospace components that must endure extreme conditions. By integrating CNC plasma cutting, manufacturers can achieve intricate designs and precise cuts that are critical for the performance and safety of aircraft and spaceflight vehicles. The technology's ability to handle complex geometries further underscores its role in revolutionizing metal fabrication in manufacturing, ultimately leading to innovations that push the boundaries of engineering and design.

Innovative Applications of Cnc Plasma Cutting Machine in Various Industries

| Industry | Application | Benefits | Technology Used |

|---|---|---|---|

| Automotive | Frame and Chassis Parts | Increased precision, reduced waste | CNC Plasma Cutting |

| Aerospace | Wing and Fuselage Components | Weight reduction, enhanced structural integrity | Advanced CNC Systems |

| Construction | Structural Steel Fabrication | Faster assembly times, customized designs | Plasma Cutting Machines with Automation |

| Shipbuilding | Hull and Deck Components | Improved safety, cost efficiency | CNC Plasma Cutting Technology |

| Art and Design | Metal Sculptures and Decor | Enhanced creativity, unique designs | Creative CNC Plasma Systems |

Unleashing Creativity: CNC Plasma Cutting for Artistic Applications

CNC plasma cutting machines are revolutionizing artistic expressions across various industries. With precision cutting capabilities, artists can transform metal sheets into stunning sculptures, intricate architectural elements, and personalized art pieces. The versatility of plasma cutting allows for the creation of unique designs that range from abstract art to detailed representations, making it an essential tool for modern artists looking to push the boundaries of their creativity.

Tips for getting started with CNC plasma cutting in art include understanding the software that drives the machine. Familiarizing oneself with CAD (Computer-Aided Design) applications can enhance design efficiency and ensure that intricate details are captured accurately. Additionally, experimenting with different materials can lead to surprising results; artists should try out various thicknesses and types of metal to see how each responds to plasma cutting techniques.

Another crucial tip is to prioritize safety measures while working with CNC plasma cutting machines. Ensuring proper ventilation, wearing protective gear, and understanding the machine’s operational guidelines will not only safeguard artists but also enhance their creative experience. Embracing these practices can lead to a more fruitful and enjoyable artistic journey, where creativity meets engineering innovation.

Efficiency and Precision: Why Industries Prefer CNC Plasma Cutting

CNC plasma cutting machines have emerged as a game-changer in various industries due to their undeniable efficiency and precision. The demand for these cutting-edge tools is reflected in the global cutting equipment market, which has developed into a critical pillar in modern manufacturing. As per recent industry reports, the market size is anticipated to grow significantly, reaching USD 196 billion by 2034, driven by advancements in CNC technology and the rising need for high-quality manufacturing processes.

The accuracy provided by CNC plasma cutting machines is unmatched. This technology offers industries the ability to create intricate designs and precise cuts with minimal waste, enhancing overall productivity. In particular, studies indicate that companies leveraging CNC plasma cutting find efficiencies in metal fabrication, with reductions in both cutting time and labor costs. Reports highlight a growing preference for mechanized plasma cutting systems, as they streamline operations while ensuring high-quality output – a crucial factor for industries where precision is paramount.

Innovative Applications of CNC Plasma Cutting Machine in Various Industries

Cost-Effective Solutions: The Economic Benefits of CNC Plasma Cutting

CNC plasma cutting machines are revolutionizing various industries by providing cost-effective solutions that enhance productivity and reduce operational expenses. As manufacturers increasingly turn to automation and digital technologies, the economic benefits of CNC plasma cutting become apparent. These machines enable precise cutting of metals and other materials, significantly minimizing waste and maximizing efficiency. This technology not only accelerates production times but also allows for intricate designs that were previously challenging to achieve with traditional cutting methods.

Moreover, the growing demand for high-precision machining is fueling the expansion of the CNC machine tools market. With projections estimating substantial growth in the plasma cutting sector, businesses can reap the rewards of investing in these advanced technologies. By incorporating CNC plasma cutting into their operations, small and medium enterprises can not only enhance their competitive edge but also align themselves with the sustainability goals that are increasingly important in the current economic landscape. Embracing such innovative applications not only empowers efficient production but also contributes to the circular economy by promoting resource optimization and waste reduction.

Enhancing Production Capabilities: CNC Plasma Cutting in Automotive Industries

CNC plasma cutting technology is revolutionizing the automotive industry by enhancing production capabilities and efficiency. This advanced machining process allows for precise cutting of various metals, enabling manufacturers to produce complex shapes and components with high accuracy. The incorporation of CNC plasma cutting machines significantly reduces production time, thereby accelerating the overall manufacturing process. As automotive designs become increasingly intricate, the versatility of CNC plasma cutting ensures that manufacturers can meet evolving design requirements while maintaining strict quality standards.

Moreover, the growth of the automotive sector is closely linked to advancements in CNC technology. By leveraging mechanized plasma cutting, companies can achieve greater scalability in their operations, allowing them to adapt swiftly to market demands. With the automotive industry projected to grow significantly in the coming years, the integration of innovative CNC plasma cutting solutions will be crucial for manufacturers looking to enhance their competitive edge. As investments in automation and smart manufacturing increase, the role of CNC plasma cutting in automotive applications will undoubtedly expand, showcasing its pivotal contribution to the industry's future.

Related Posts

-

How to Choose the Best Cnc Plasma Cutting Machine for Your Business Needs

-

Ultimate Guide to Maximizing Efficiency with CNC Plasma Cutting Machines

-

Resilient Growth of Chinese Manufacturers in the Face of US China Tariffs and the Rise of Best Small CNC Plasma Cutters

-

10 Ways Cnc Plasma Cutting Tables Transform Your Manufacturing Efficiency

-

Global Manufacturing Guidelines for Cnc Plasma Cutting Machine Innovations

-

Challenges When Choosing the Right Best Cnc Plasma Table for Your Business Needs