Industry Applications of Laser Cutting Tables and 7 Benefits You Might Not Know

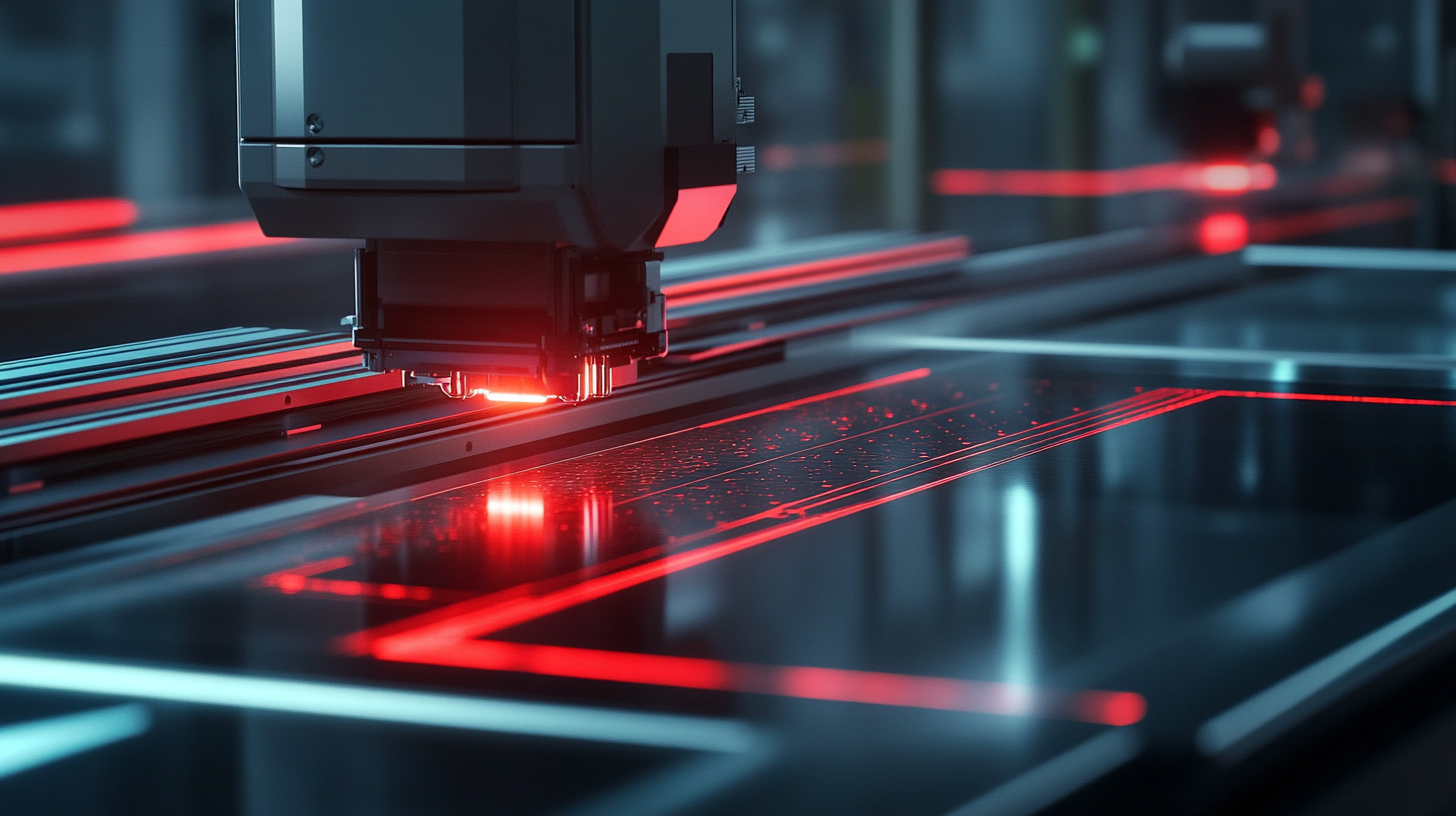

In recent years, the adoption of Laser Cutting Tables has revolutionized various industries by significantly enhancing precision and efficiency in fabrication processes. According to a report by Allied Market Research, the global laser cutting market is projected to reach $5.66 billion by 2025, growing at a CAGR of 5.6% from 2018 to 2025. This growth is largely driven by advancements in laser technology, enabling manufacturers to achieve intricate cutting patterns and faster processing times. The ability to work with a variety of materials, including metals, plastics, and wood, has made laser cutting an indispensable technology across sectors such as automotive, aerospace, and electronics.

Moreover, the benefits of using Laser Cutting Tables extend beyond mere accuracy and speed. A study conducted by MarketsandMarkets indicated that companies employing laser cutting technology have reported a 30% reduction in production costs and a significant decrease in material waste. The versatility and adaptability of laser cutting applications also allow businesses to respond more effectively to market demands, nurturing innovation and reducing lead times. As industries continue to explore the full potential of laser cutting, understanding its versatile applications and hidden benefits becomes crucial for staying competitive in an ever-evolving marketplace.

Advantages of Laser Cutting Tables in Various Industries

In various industries, laser cutting tables are revolutionizing the manufacturing process due to their myriad advantages. One of the most notable benefits is precision. Laser cutting offers unparalleled accuracy, allowing for intricate designs and detailed cuts that traditional methods struggle to achieve. According to recent market statistics, the laser cutting machine market is projected to grow significantly, driven by demand from sectors like textiles and lumber, where intricate cutting patterns are essential for productivity and quality. Another advantage of laser cutting tables is their efficiency. The high-speed operation not only reduces production time but also minimizes material waste, leading to cost savings. For instance, in the textile and apparel industry, automated cutting solutions are increasingly being adopted as factories strive for seamless integration into Industry 4.0, enhancing both manufacturing capabilities and operational workflows. Reports indicate that automated systems can increase production speed by up to 30%, underscoring the technology's impact. Additionally, the versatility of laser cutting tables allows them to service a variety of applications, from creating complex parts in aerospace to detailed carvings in woodworking. The use of focused laser beams enables these machines to cut through a range of materials, including metals, plastics, and textiles, making them invaluable across industries. Recent developments in laser technology continue to push the boundaries of what’s possible, ensuring these tools remain at the forefront of industrial innovation.

Innovative Industries Utilizing Laser Cutting Technology

Laser cutting technology has transformed various industries by providing precision and efficiency in manufacturing processes. Innovative industries are increasingly adopting laser cutting tables to enhance production capabilities and streamline workflows. From aerospace to automotive, the versatility of laser cutting machines enables them to cater to diverse materials such as metals, plastics, and wood, making them indispensable in modern production lines.

In the aerospace sector, laser cutting is used for creating complex parts with intricate designs that demand high accuracy. These cutting tables allow for the efficient separation of lightweight materials, thus contributing to fuel efficiency and performance optimization in aircraft. Furthermore, in the automotive industry, manufacturers utilize laser cutting for both prototyping and mass production, achieving cleaner cuts and reduced waste. The ability to quickly adapt designs ensures that manufacturers can keep pace with evolving consumer preferences and regulatory changes.

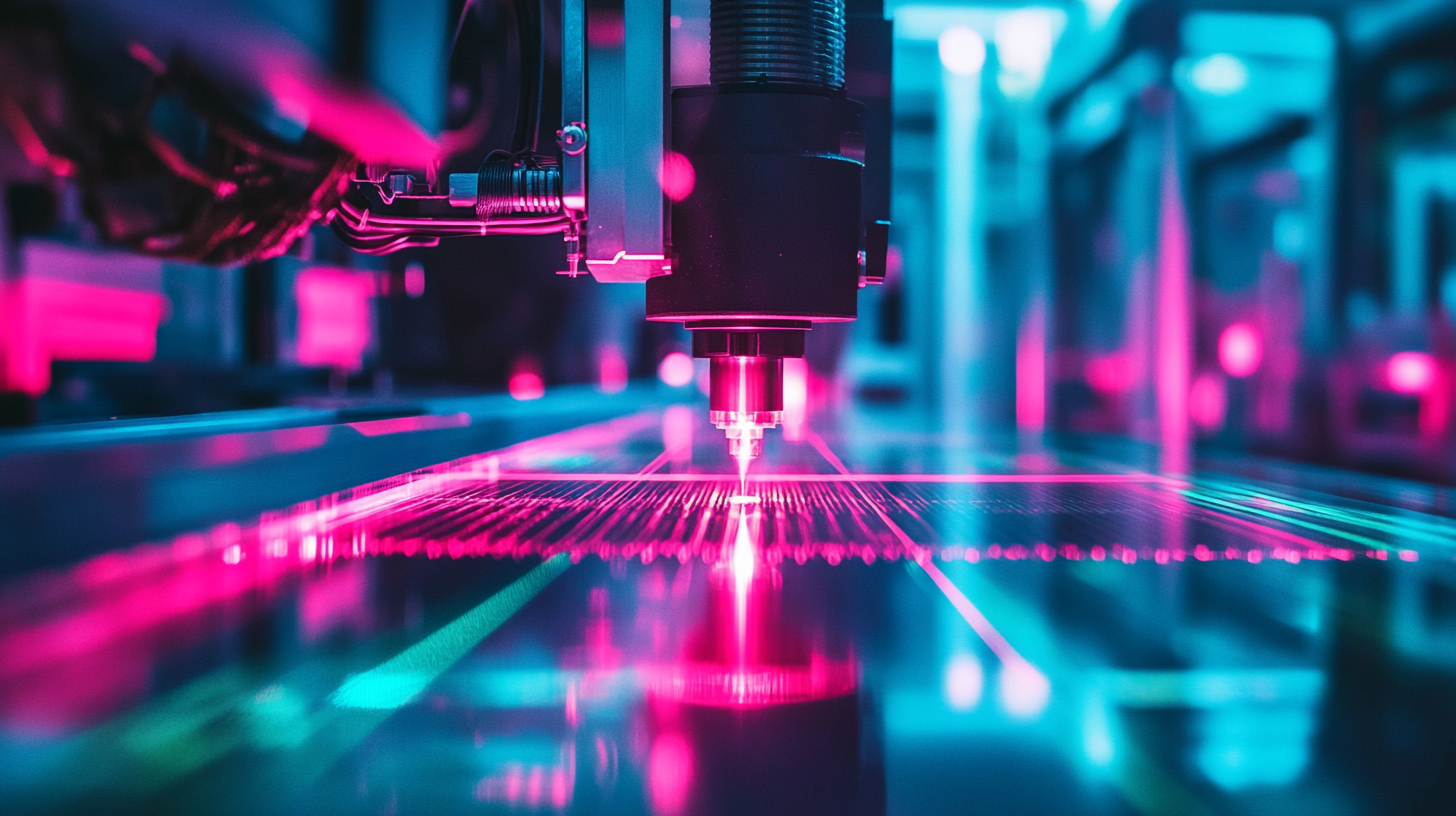

The benefits of laser cutting technology extend beyond mere precision. Industries are also experiencing significant time savings and lower operational costs due to the automation of cutting processes. Laser cutting tables often come equipped with advanced software that aids in design modifications and improves overall workflow. This innovation not only reduces lead times but also boosts product consistency, making it a game-changer for industries aiming for high quality and reliability in their outputs.

Key Benefits of Laser Cutting You May Overlook

Laser cutting technology has revolutionized various industries, offering precision and efficiency that traditional cutting methods simply cannot match. While most people are aware of the primary advantages like speed and accuracy, there are several key benefits that are often overlooked. These hidden advantages can significantly enhance production capabilities and overall competitiveness.

One of the lesser-known benefits of laser cutting is its ability to handle complex designs with ease. The fine control offered by laser systems allows for intricate patterns and details that are difficult to achieve with other methods. This capability not only broadens design possibilities but also reduces the need for secondary operations, streamlining the production process and saving valuable time and resources.

Another advantage is the minimal material wastage associated with laser cutting. The precision of the laser beam results in narrower kerf widths, meaning less unused material is discarded. This efficiency is particularly important in industries where material costs are high and environmental considerations are paramount. Furthermore, laser cutting can incorporate advanced software that optimizes the layout of parts, maximizing material utilization and reducing scrap.

Additionally, laser cutting tables can be set up for automatic operation, reducing labor costs and minimizing human error. This automation allows businesses to increase their production capacity while maintaining high quality standards. The flexibility of laser cutting technology also means it can easily adapt to various materials, making it a versatile solution for businesses looking to diversify their offerings without significant investment in new equipment.

Comparative Analysis: Laser Cutting vs. Traditional Methods

When evaluating the effectiveness of laser cutting tables compared to traditional cutting methods, several factors emerge that highlight the advanced capabilities of laser technology. One significant advantage is precision. Laser cutting provides exceptionally accurate cuts due to the focused energy source, which can easily navigate intricate designs and produce complex shapes. This precision is often unattainable with traditional methods, particularly when handling detailed patterns or small parts.

Additionally, laser cutting tables offer faster processing times. Traditional methods, such as saws or manual blades, can be slower and often require time-consuming setup and tooling changes. In contrast, laser cutters can swiftly adjust to different designs and materials, allowing businesses to enhance productivity significantly. This speed not only streamlines production but also reduces lead times, making it an attractive option for industries that demand quick turnaround.

Another factor to consider is material versatility. Laser cutting can efficiently work with a wide range of materials, including metals, plastics, and wood, while traditional methods may have restrictions based on the tools used. This adaptability is particularly beneficial for manufacturers looking to diversify their product offerings without investing heavily in multiple types of machinery. The benefits of laser cutting extend beyond efficiency and adaptability; they open new avenues for innovation in product design and manufacturing processes.

Future Trends in Laser Cutting Applications Across Sectors

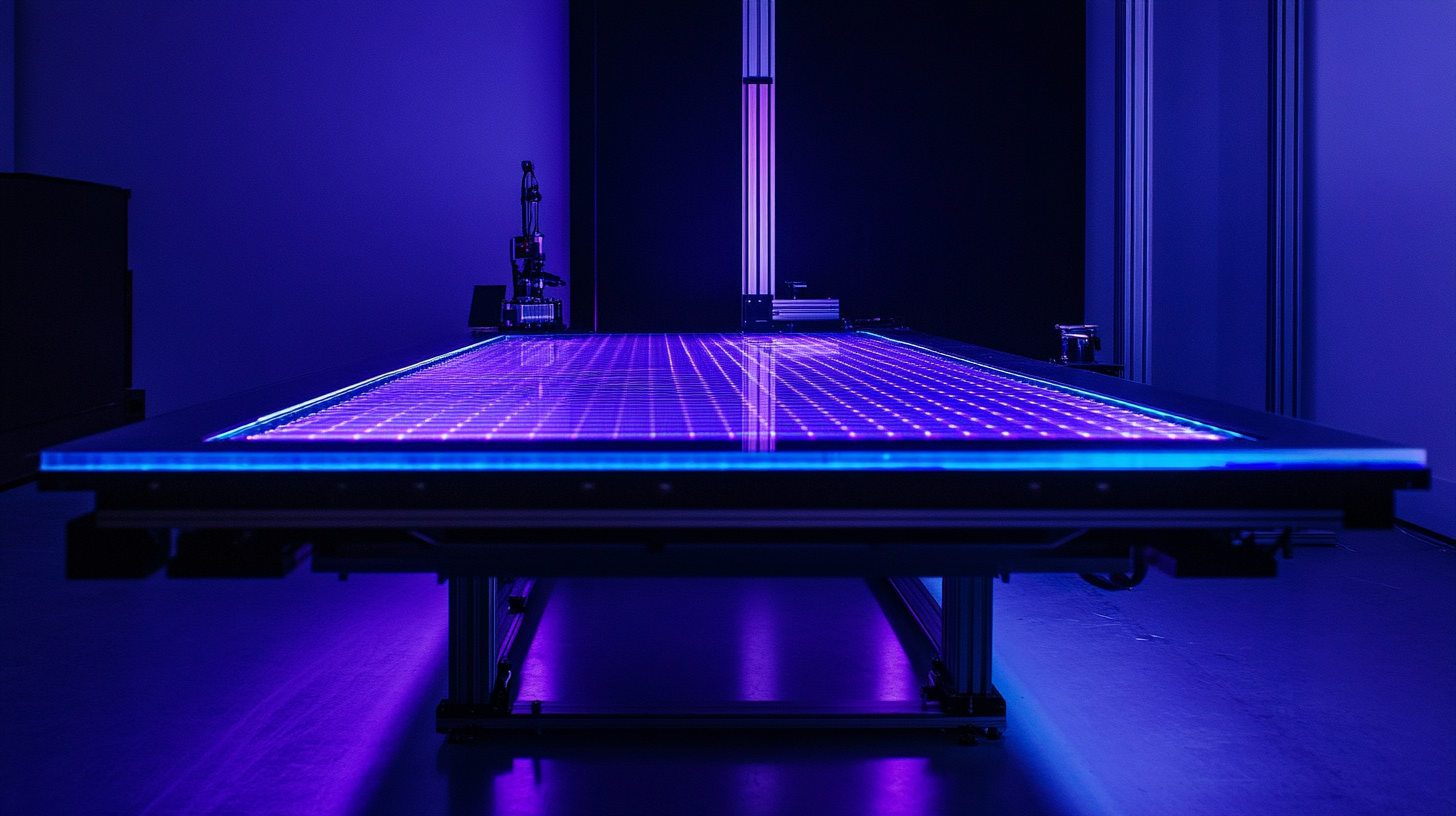

The future of laser cutting applications is poised for significant transformation across various sectors, driven by advancements in technology and increasing demand for precision and efficiency. Industries such as automotive, aerospace, and electronics are adopting laser cutting tables not only for traditional applications but also for innovative uses that enhance production capabilities. With the integration of automation and artificial intelligence, laser cutting processes are becoming more intelligent, enabling real-time adjustments and improved quality control.

One of the most promising trends is the rise of multi-material cutting capabilities. Modern laser cutting tables are now able to handle a diverse range of materials, including metals, plastics, and composites. This versatility allows manufacturers to streamline their operations by reducing setup times and minimizing the need for multiple cutting tools. Furthermore, as sustainability becomes a priority, laser cutting technology is evolving to minimize waste and energy consumption, making it a more environmentally friendly choice.

Additionally, the adoption of cloud-based software solutions is paving the way for more flexible and interconnected manufacturing environments. By leveraging data analytics, companies can gain insights into their production processes, optimizing performance and maintenance schedules. As industries continue to harness the power of laser cutting technology, we can expect to see an expansion in its applications, making it an indispensable tool for modern manufacturing and design.