How to Optimize Your Projects with Advanced CNC Cutter Technology

In today’s competitive manufacturing landscape, optimizing projects is essential for efficiency and cost-effectiveness. One pivotal technology that stands at the forefront of this optimization is the CNC cutter. These advanced machines offer unparalleled precision and versatility, enabling manufacturers to execute intricate designs and patterns with ease. By leveraging the capabilities of CNC cutters, businesses can significantly enhance their production processes, reduce material waste, and streamline workflows. This guide will delve into the various strategies and best practices to optimize your projects through the innovative use of CNC cutter technology, ensuring that you stay ahead in the market while maximizing both productivity and quality. Embrace the future of manufacturing by understanding how advanced CNC cutters can reshape your project management and operational efficiency.

Understanding Advanced CNC Cutter Technology: Key Features and Benefits

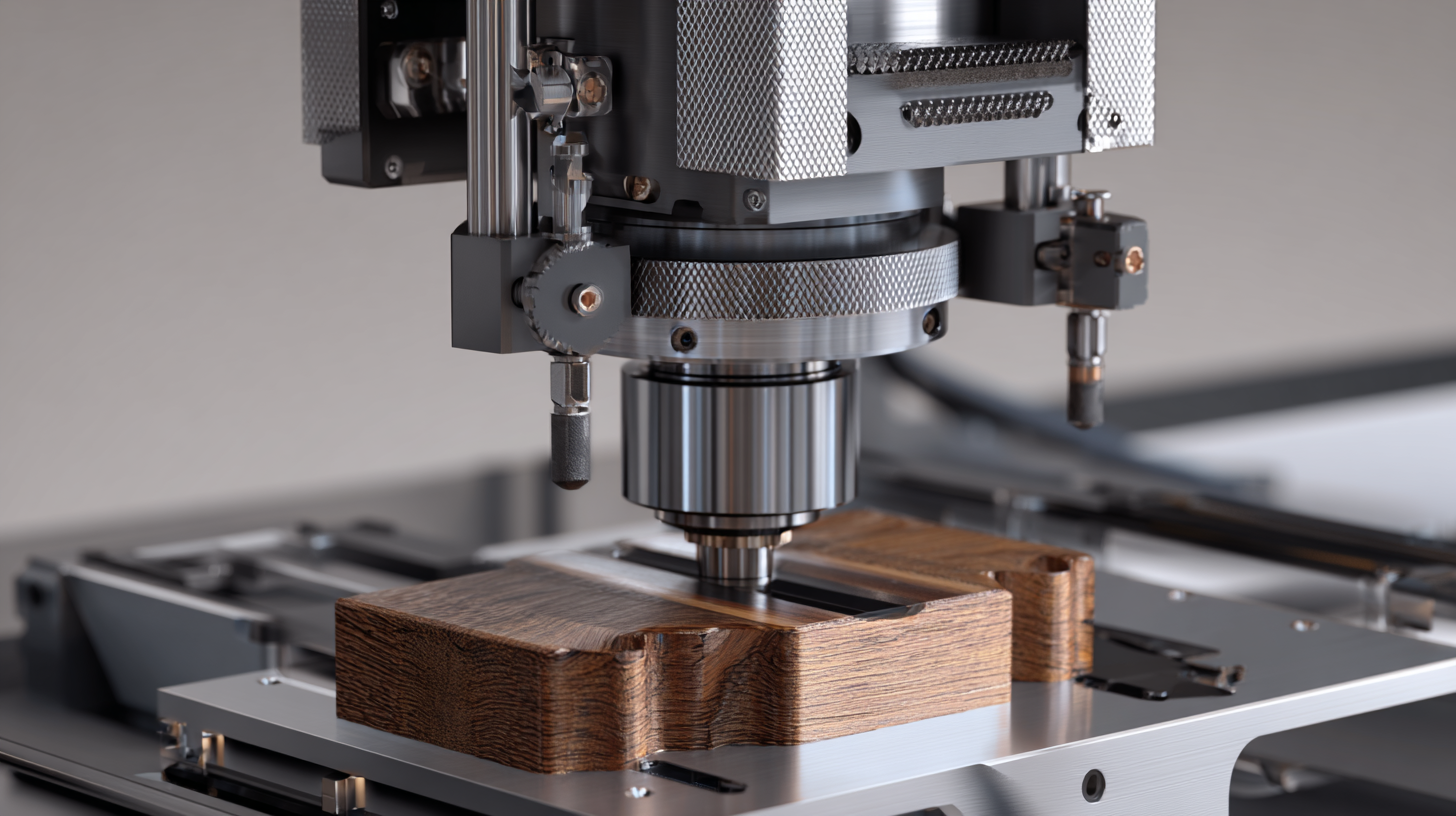

Advanced CNC cutter technology has revolutionized the landscape of digital manufacturing. By integrating precision engineering with cutting-edge software, these machines provide unparalleled accuracy and efficiency, making them essential in various industries. Key features that set advanced CNC cutters apart include their ability to handle complex geometries, high-speed machining capabilities, and automated tool management systems. These enhancements not only streamline production processes but also elevate the quality of finished products.

Tip 1: To maximize the benefits of advanced CNC technology, invest in staff training. Well-trained operators can utilize the full range of capabilities offered by these machines, ensuring optimal performance and reducing the likelihood of costly errors.

In addition to boosting productivity, advanced CNC cutters also contribute to sustainability efforts. Their precise cutting reduces material waste, and many models are designed to operate with greater energy efficiency.

Tip 2: Regular maintenance of CNC machines is critical for sustaining their longevity and performance. Establish a routine check-up and maintenance plan to keep your equipment in peak condition, which can further enhance your operational efficiency.

Embracing advanced CNC cutter technology not only accelerates product development but also fosters innovation and competitiveness in the manufacturing sector.

Impact of CNC Cutter Precision on Material Utilization and Waste Reduction

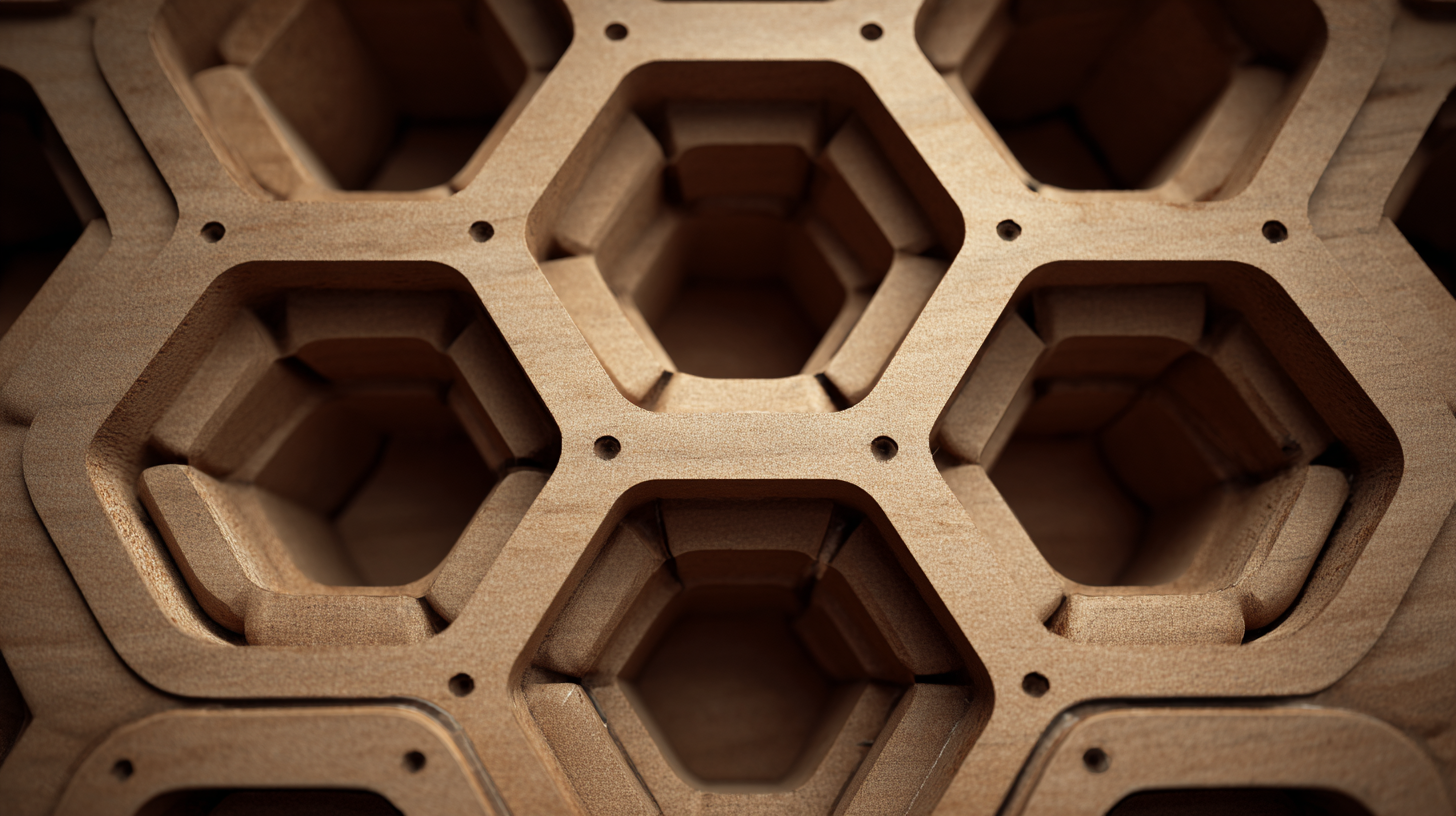

Advanced CNC cutter technology plays a crucial role in enhancing precision in manufacturing processes. The accuracy of CNC cutters allows for intricate designs and tight tolerances, which directly impacts material utilization. With advanced settings and algorithms, CNC machines can create complex shapes with minimal waste, maximizing the use of the raw material. This precision not only reduces discard rates but also allows manufacturers to optimize their inventory, leading to significant cost savings.

Advanced CNC cutter technology plays a crucial role in enhancing precision in manufacturing processes. The accuracy of CNC cutters allows for intricate designs and tight tolerances, which directly impacts material utilization. With advanced settings and algorithms, CNC machines can create complex shapes with minimal waste, maximizing the use of the raw material. This precision not only reduces discard rates but also allows manufacturers to optimize their inventory, leading to significant cost savings.

Additionally, the reduction of waste through CNC cutter precision positively influences environmental sustainability. By minimizing excess material and ensuring that cuts are executed with high accuracy, businesses can contribute to less landfill waste and a lower carbon footprint. Furthermore, the efficient use of materials encourages a more responsible approach to resource management within the industry. As CNC technology continues to evolve, its ability to refine manufacturing processes will play a vital role in driving both economic and ecological benefits.

Evaluating Cost-Effectiveness: ROI of Upgrading to Advanced CNC Cutting Systems

The decision to upgrade to advanced CNC cutting systems is often driven by the need for greater efficiency and precision in production. However, it's crucial to evaluate the cost-effectiveness and potential return on investment (ROI) associated with such an upgrade. One key factor to consider is the long-term savings on labor and material costs due to improved cutting accuracy and reduced waste. Manufacturers that invest in state-of-the-art CNC technology often find that their production capabilities increase significantly, allowing them to take on more complex projects without needing a proportional increase in overhead.

**Tips:** When considering an upgrade, conduct a thorough analysis of your current process inefficiencies. Gather data on cycle times, material usage, and operational costs. Moreover, test any new technology through pilot projects to assess the impact on your production line before committing to a full-scale upgrade.

Another aspect to think about is the potential for enhanced customer satisfaction. Advanced CNC systems can enable companies to meet tighter tolerances and deliver products faster, ultimately leading to higher customer retention. This level of precision can also open doors to new markets and higher-value projects, enhancing overall profitability.

**Tips:** Develop a feedback loop with customers to identify areas where improved precision could meet their needs better. Regularly review market trends to align your capabilities with upcoming demands in your industry, ensuring that the investment in technology corresponds to both market needs and company goals.

Integrating Automation: Enhancing Workflow Efficiency with CNC Cutters

Integrating automation into CNC cutter technology can significantly enhance workflow efficiency in a variety of industries. By combining cutting-edge CNC machines with automated processes, companies can streamline their operations, reduce manual labor, and minimize human errors. This integration allows for the rapid setup of cutting operations, where once time-consuming adjustments are now automatically calibrated, enabling a faster turnaround time for projects. As a result, businesses can meet tight deadlines while maintaining high-quality output.

Moreover, the incorporation of automated systems provides real-time monitoring and data collection. This technological advancement allows operators to analyze performance metrics, optimize cutting parameters, and anticipate maintenance needs. By leveraging machine learning algorithms, CNC systems can improve their precision over time, leading to enhanced product quality and reduced waste. Ultimately, embracing automation in CNC cutting not only improves efficiency but also empowers companies to innovate and stay competitive in an ever-evolving market landscape.

Real-World Case Studies: Successful Project Outcomes Using CNC Technology

Advanced CNC (Computer Numerical Control) cutter technology has transformed the manufacturing landscape, enabling businesses to achieve precise and efficient project outcomes. A recent report from the International Association of Machining Technology revealed that companies using CNC technology reported a 30% increase in production efficiency and a 20% reduction in material waste. This significant improvement can be illustrated through various case studies from diverse sectors.

For instance, a furniture manufacturing company implemented CNC cutting machines in their production line, resulting in a remarkable turnaround. The integration of CNC technology allowed them to optimize intricate designs and streamline their cutting processes. According to their internal metrics, they experienced a 50% decrease in lead time, leading to a 15% boost in customer satisfaction ratings within six months. Similarly, a metal fabrication shop utilized advanced CNC technology to enhance their prototyping capabilities, achieving an impressive 40% reduction in errors and scrap rates. These real-world examples underscore how firms leveraging CNC cutters can achieve exemplary project results while enhancing overall operational efficiency.

As the manufacturing industry continues to evolve, the adoption of advanced CNC cutter technology is proving to be a game-changer, driving innovation and competitive advantage. Studies indicate that by 2025, nearly 70% of manufacturers plan to integrate CNC machines into their processes, highlighting the growing recognition of technology's potential in optimizing project outcomes across the board.

Optimization of Projects with Advanced CNC Cutter Technology

This bar chart illustrates the success outcomes of various projects that employed advanced CNC cutter technology. The data shows the percentage of project completion time reduction and cost savings across different industries.

Related Posts

-

Navigating 2025's Cutting-Edge CNC Innovations: Proven Strategies to Optimize Your Best CNC Cutter Investments

-

7 Reasons Why the Best CNC Cutter Can Transform Your Manufacturing Process

-

Unlock Precision and Efficiency in Manufacturing with Our Advanced Cnc Cutters

-

Exploring Real World Applications of the Best Plasma Torch Across Diverse Industries

-

Mastering the Art of Plasma Cutting with the Best Plasma Cutter Guide

-

Unveiling the Best Plasma CNC Machine Specifications and How to Choose the Right One