Overcoming Common Challenges in Sourcing the Best CNC Tables for Your Business

In today's competitive manufacturing landscape, sourcing the best CNC tables has become a pivotal challenge for businesses aiming to enhance efficiency and precision in their operations. According to a report by MarketsandMarkets, the global CNC machinery market is projected to grow to $117.93 billion by 2026, highlighting the increasing demand for advanced CNC solutions. However, many businesses struggle with selecting the right CNC table due to factors such as varying quality standards, material specifications, and technological advancements. This blog will delve into the common challenges faced when sourcing CNC tables and provide valuable insights on how to navigate these obstacles effectively. By understanding the key criteria for evaluating manufacturers, businesses can streamline their procurement processes and ultimately invest in high-quality CNC tables that cater to their specific needs.

Identifying Key Specifications for CNC Tables That Meet Your Business Needs

When sourcing CNC tables for your business, it's essential to identify key specifications that align with your operational demands. First and foremost, consider the size and capacity of the CNC table. Evaluate the dimensions of the materials you intend to work with and ensure the table can accommodate larger projects without compromising precision or stability. Additionally, pay close attention to the weight capacity, as this will determine the types of materials and components you can efficiently handle.

Another critical aspect is the rigidity and construction of the CNC table. A robust design minimizes vibrations during operation, which is vital for maintaining accuracy in intricate machining tasks. You should also assess the type of drive system, whether it's rack and pinion, ball screw, or others, as this impacts both speed and precision. By understanding these specifications, you can make an informed decision that not only meets your current needs but also positions your business for future growth and adaptability in an ever-evolving manufacturing landscape.

Understanding Common Sourcing Challenges in the CNC Table Market

Sourcing the best CNC tables for your business can be a daunting task, primarily due to the myriad of challenges that come with navigating the CNC table market. One of the most common issues businesses face is the overwhelming variety of options available. With numerous manufacturers offering diverse specifications, features, and price points, pinpointing the most suitable table for your specific needs can be like finding a needle in a haystack. It becomes essential to define your requirements clearly to avoid procurement pitfalls.

Moreover, quality assurance is a significant concern in the sourcing process. Ensuring that the CNC tables meet industry standards and deliver consistent performance is crucial for maintaining operational efficiency. Many suppliers may promise high-quality products, but the reality can differ significantly. To overcome this challenge, it is advisable to conduct thorough research and seek reviews or testimonials from other businesses. Establishing a reliable relationship with manufacturers and requiring samples or demonstrations before committing can also help mitigate risks associated with quality discrepancies in CNC table sourcing.

Overcoming Common Challenges in Sourcing the Best CNC Tables for Your Business

| Challenge | Description | Impact on Business | Solutions |

|---|---|---|---|

| Quality Control | Inconsistent product quality can lead to defects and operational delays. | Increased costs and customer dissatisfaction. | Implementing rigorous quality assurance processes and selecting certified suppliers. |

| Supplier Reliability | Dependence on suppliers who may struggle to meet deadlines. | Potential production halts and loss of revenue. | Building relationships with multiple reliable suppliers. |

| Cost Management | Fluctuating prices for materials and services. | Budget overruns and reduced profit margins. | Regular market analysis and long-term contracts with fixed pricing. |

| Technological Changes | Keeping up with evolving CNC technology requires investment. | Obsolescence and increased operational costs. | Investing in training and gradual upgrades to equipment. |

| Market Competition | Intense competition may drive prices down. | Squeezed margins and potential loss of market share. | Differentiating products through innovation and quality. |

Evaluating Different Types of CNC Tables: Which One Fits Your Operations?

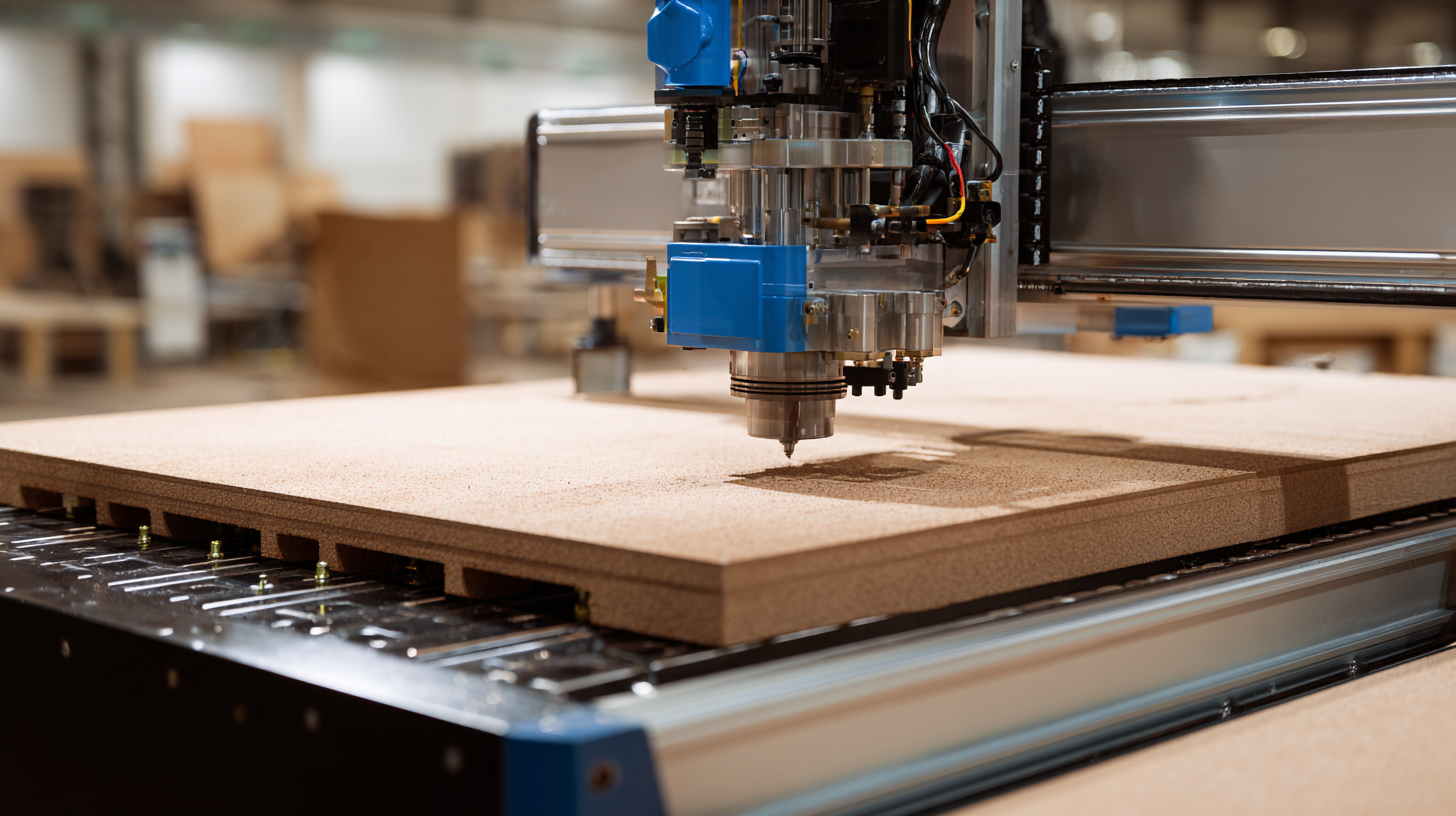

When evaluating different types of CNC (Computer Numerical Control) tables for your operations, it's crucial to consider the specific needs of your business. There are various categories of CNC tables available, each designed to address different tasks and materials. For instance, if your operations focus on woodworking, investing in a CNC router table would be advantageous due to its ability to handle intricate designs in softer materials. On the other hand, if your work involves metal fabrication, a CNC milling table equipped with robust capabilities would be more suitable, providing precision and durability.

Additionally, it's important to assess the size and workspace requirements of each CNC table variant. A compact CNC machine may be ideal for smaller shops with limited floor space, while larger operations might benefit from expansive models that accommodate bigger projects and advanced capabilities. Furthermore, evaluating factors such as software compatibility, ease of use, and maintenance needs can significantly impact your decision. By thoroughly examining these aspects, you can ensure that the CNC table you select will effectively support your production goals and enhance overall operational efficiency.

Comparing Suppliers: How to Choose the Right Manufacturer for CNC Tables

When it comes to sourcing the best CNC tables for your business, selecting the right manufacturer is crucial. The evolving landscape of automation and robotics, highlighted by recent advancements and innovations, indicates that a careful evaluation of suppliers is essential. A report from an industry research firm suggests that the global market for CNC machines is expected to reach several billion dollars by 2025, driven primarily by increased demand in sectors such as construction and manufacturing. By comparing suppliers based on their technology integration, operational efficiency, and client reviews, businesses can make informed decisions that align with their operational needs.

**Tip:** Always assess a manufacturer’s production capabilities and technological advancements, such as their use of AI and robotics in the production process. A supplier who invests in these areas is more likely to provide CNC tables that meet your specific requirements efficiently.

Furthermore, scrutinize the after-sales support and warranty options offered by manufacturers. Collaborating with a partner who provides not just equipment but ongoing support can significantly enhance your operational productivity. Ensuring that your supplier is well-versed in industry standards and innovations is key to maintaining competitiveness in an ever-evolving market.

**Tip:** Engaging in direct communication with potential suppliers can yield insights into their responsiveness and customer service, vital factors for any long-term partnership. Aim to choose manufacturers who demonstrate a commitment to continuous improvement and customer satisfaction.

Maximizing ROI: Strategies to Optimize Your CNC Table Investment

When investing in CNC tables, maximizing your return on investment (ROI) is crucial for long-term success. One effective strategy is to thoroughly assess your specific operational needs before making a purchase. Understanding what tasks your CNC table will tackle—be it machining, cutting, or engraving—helps to select a model that not only fits your current requirements but can also scale with your business as it grows. Prioritizing versatility and precision in your choice can lead to greater productivity and efficiency, directly impacting your bottom line.

Another key approach to optimizing your CNC table investment is to focus on routine maintenance and operator training. Implementing a proactive maintenance schedule minimizes downtime and prolongs the lifespan of your equipment. Additionally, investing in training for your operators ensures they are skilled in utilizing the machine's full capabilities, reducing errors and increasing output quality. Ultimately, the combination of proper equipment selection, regular upkeep, and skilled operators creates a powerful synergy that maximizes ROI, enabling your business to thrive in a competitive market.