What is a Plasma Table? Unlocking the Power of Precision Cutting in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, precision and efficiency are paramount. A Plasma Table, a sophisticated cutting tool that utilizes a high-velocity jet of ionized gas to cut through various materials, is emerging as a critical component in achieving these goals. According to a report by Grand View Research, the global metal fabrication market size is expected to reach USD 285.16 billion by 2027, driven largely by technologies like plasma cutting that enhance productivity and accuracy. Plasma Tables not only streamline the manufacturing process but also significantly reduce material waste, making them a vital asset in industries ranging from automotive to aerospace. As manufacturers seek to adopt advanced technologies to remain competitive, understanding the capabilities and benefits of Plasma Tables is essential for unlocking their full potential in precision cutting.

The Evolution of Cutting Technology: From Manual to Plasma Tables

The evolution of cutting technology has seen a remarkable transition from manual methods to highly advanced systems like plasma tables. In the early days of manufacturing, cutting was predominantly performed using handsaws, chisels, and other manual tools. This approach, while effective in skilled hands, was time-consuming and often resulted in inconsistent quality. As industries expanded and the demand for precision grew, manufacturers began to seek more efficient and accurate alternatives.

The introduction of plasma cutting technology marked a significant milestone in this evolution. Plasma tables utilize a stream of ionized gas, or plasma, to slice through various materials with extreme precision. This advancement allows for intricate designs and cleaner cuts, making it a favored choice for industries ranging from automotive to aerospace. The automation that comes with plasma tables not only boosts productivity but also minimizes human error, thereby enhancing the overall quality of the finished product.

As we look to the future, it’s clear that plasma cutting will continue to play a crucial role in shaping modern manufacturing practices.

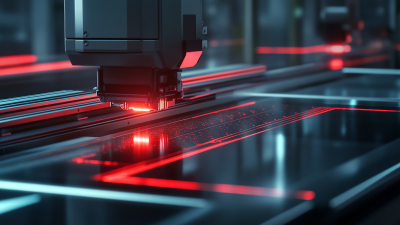

Understanding the Mechanics: How Plasma Tables Work in Precision Cutting

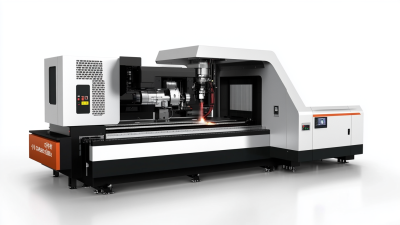

Plasma tables have revolutionized the landscape of precision cutting in modern manufacturing, providing unmatched accuracy and efficiency. At the core of their operation is the plasma cutting process, where high-velocity plasma jets are utilized to melt and cut through conductive materials. According to a report by MarketsandMarkets, the global plasma cutting equipment market is projected to reach $9.2 billion by 2026, highlighting a growing adoption of this technology across various industries. The precision of plasma tables, often achieving tolerances within 0.01 inches, is a key factor driving this market growth.

The mechanics behind plasma tables involve several critical components: a CNC (computer numerical control) system, a plasma torch, and a robust cutting bed. The CNC system directs the movement of the plasma torch with exceptional precision, which is essential for creating intricate designs in metals like steel and aluminum. A recent study by Technavio identified that plasma cutting can improve productivity by up to 35% when compared to traditional cutting methods. This efficiency, coupled with the ability to cut complex shapes and thicknesses up to several inches, makes plasma tables an indispensable tool in sectors such as automotive, aerospace, and fabrication. As industries continue to seek advancements in manufacturing processes, plasma cutting technology stands at the forefront of innovation.

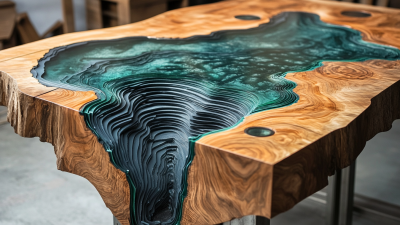

Industry Applications: Where Plasma Tables Shine in Modern Manufacturing

Plasma tables are transforming modern manufacturing with their precision cutting capabilities across various industries. These advanced machines utilize high-temperature plasma to cut through materials like metal and composite structures with remarkable accuracy. According to recent market analysis, the plasma cutting machine market is expected to witness substantial growth, with a projected size reaching USD 246.5 million by 2033, growing at a compound annual growth rate (CAGR) of 7%. This surge is driven by the increasing demand for automation in manufacturing processes and the efficiency offered by CNC-enabled plasma cutting machines.

Industries such as automotive, aerospace, and heavy machinery are particularly benefiting from plasma tables. They excel in applications requiring intricate designs and quick turnaround times, allowing manufacturers to maintain a competitive edge. Furthermore, the welding materials market is anticipated to be worth $22.53 billion by 2030, highlighting the interconnection between plasma cutting technology and welding applications as manufacturers seek innovative solutions to enhance productivity.

Tip: When considering plasma cutting for your manufacturing needs, evaluate the specific material types and thicknesses you'll be working with. Choosing the right plasma table equipped for your applications can significantly improve operational efficiency and output quality. Additionally, investing in training for operators can maximize the benefits of using these advanced cutting technologies.

Cost Efficiency and Speed: The Economic Advantages of Using Plasma Tables

In the realm of modern manufacturing, plasma tables have emerged as a game-changing technology, particularly noted for their cost efficiency and speed. According to a report by MarketsandMarkets, the global plasma cutting equipment market is projected to reach $4.6 billion by 2026, growing at a CAGR of 5.2%. This growth underscores the increasing reliance on plasma cutting for various industries, driven by the technology’s ability to deliver high-quality cuts at a fraction of the traditional methods' costs.

Using plasma tables not only enhances operational speed but also significantly reduces material waste, with studies indicating that precision cutting can minimize scrap material by up to 30%. This efficiency translates into substantial cost savings for manufacturers. Additionally, the versatility of plasma tables allows them to handle a wide range of materials—like steel, aluminum, and stainless steel—making them a versatile asset on the shop floor.

Tip: When investing in a plasma table, consider models with advanced CNC capabilities for better accuracy and ease of use. Incorporating software that integrates with CAD systems can streamline operations and further reduce setup time between projects. Emphasizing training for operators can also maximize the utilization and benefits of plasma cutting technology, ensuring that companies stay competitive and efficient in their manufacturing processes.

Cost Efficiency and Speed: The Economic Advantages of Using Plasma Tables

Future Trends: Innovations Shaping the Next Generation of Plasma Cutting Tech

The landscape of plasma cutting technology is rapidly evolving, driven by innovation and the increasing demands of modern manufacturing. One of the most significant trends shaping the future of plasma cutting is the integration of advanced automation. Automatic CNC (Computer Numerical Control) plasma tables are becoming more sophisticated, enabling manufacturers to achieve higher levels of precision and efficiency in their cutting processes. With the ability to manage complex designs and adjust settings in real time, these systems can minimize waste and optimize production schedules, thereby enhancing overall productivity.

Another key innovation is the advancement of plasma cutting consumables and their capabilities. The development of specialized electrodes and nozzles is improving the quality of cuts and extending the operational life of plasma cutting systems. Additionally, innovations in plasma power sources are allowing for better energy efficiency, resulting in lower operational costs. As technologies such as IoT (Internet of Things) become more prevalent, manufacturers will also be able to implement predictive maintenance strategies, reducing downtime and ensuring that equipment runs smoothly, further pushing the boundaries of what's possible with plasma cutting in the future.

What is a Plasma Table? Unlocking the Power of Precision Cutting in Modern Manufacturing - Future Trends: Innovations Shaping the Next Generation of Plasma Cutting Tech

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| Precision Cutting | Utilizes plasma technology to cut metal with high accuracy. | Reduces waste, enhances quality, and speeds up production. | Integration of AI for real-time adjustments and enhanced precision. |

| Versatility | Can cut various materials including steel, aluminum, and more. | Allows for a diverse range of applications in manufacturing. | Development of multi-material cutting capabilities. |

| Automation | Integration with CNC technology for automated cutting procedures. | Increases efficiency and reduces manual labor costs. | Rise of fully automated plasma systems with minimal human intervention. |

| Safety Features | Incorporates advanced safety mechanisms to protect operators. | Enhances workplace safety and compliance with regulations. | Integration of smart sensors for hazard detection. |

| Energy Efficiency | Optimizes power consumption during operation. | Lower energy costs and reduced environmental impact. | Emergence of eco-friendly plasma cutting technologies. |

Related Posts

-

Plasma Table Insights for Global Buyers 2025 Top 10 Trends Shaping the Future

-

Finding the Right Supplier for Best Plasma Table Kit and Effective Strategies for Success

-

7 Must-Know Strategies for Sourcing the Best Plasma Cutting Tables Globally

-

Resilient Growth of Chinese Manufacturers in the Face of US China Tariffs and the Rise of Best Small CNC Plasma Cutters

-

Industry Applications of Laser Cutting Tables and 7 Benefits You Might Not Know

-

Global Manufacturing Guidelines for Cnc Plasma Cutting Machine Innovations