Exploring Real World Applications of the Best Plasma Torch Across Diverse Industries

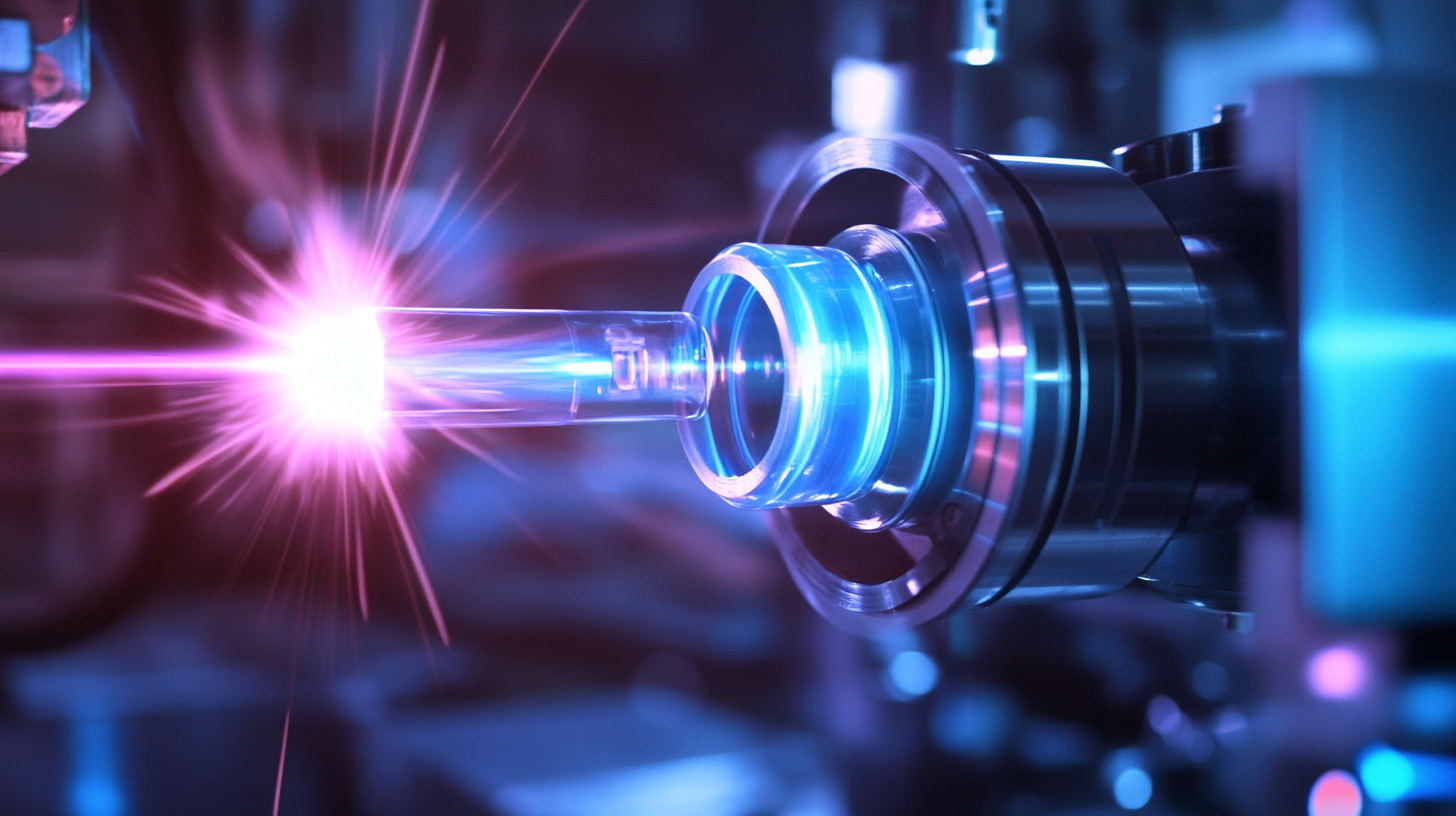

In recent years, the plasma torch has emerged as a transformative technology across various industries, redefining the standards for precision cutting, welding, and material treatment. As per a report by MarketsandMarkets, the global plasma cutting machine market is projected to reach $5.3 billion by 2026, driven by increased demand in sectors such as automotive, aerospace, and construction. This growing interest underscores the plasma torch's ability to enhance productivity and quality, making it a critical tool for manufacturers aiming for operational excellence.

Furthermore, advancements in plasma technology have led to significant improvements in efficiency and energy consumption, aligned with the industry's shift toward sustainable practices. Exploring the real-world applications of the best plasma torch reveals not only its versatility but also its pivotal role in shaping the future of manufacturing and fabrication processes across diverse industries.

Exploring the Impact of Plasma Torch Technology on Manufacturing Efficiency by 2025

As industries continue to embrace cutting-edge technologies, plasma torch systems are set to revolutionize manufacturing efficiency by 2025. This transformative tool provides enhanced precision in cutting, welding, and surface treatment, leading to significant time savings and improved product quality. Its ability to deliver high temperatures quickly makes it ideal for a variety of materials, allowing manufacturers to maintain strict tolerances while minimizing wasted resources.

Moreover, the integration of plasma torch technology into automated systems promises to further streamline production processes. With advancements in control systems and robotics, manufacturers can expect not only increased output but also reduced operational costs. By leveraging this technology, companies can adapt to the demands of a rapidly evolving market, ensuring they remain competitive in various sectors, including automotive, aerospace, and metal fabrication.

The adoption of plasma torch solutions represents a critical step toward achieving operational excellence and sustainability in manufacturing by 2025.

Market Growth Projections for Plasma Torches in Automotive, Aerospace, and Metal Fabrication Industries

The plasma torch market is witnessing significant growth, particularly in key industries such as automotive, aerospace, and metal fabrication. The global plasma cutting machine market, specifically, is projected to increase from $646.2 million in 2023 to $841.4 million by 2030, demonstrating a steady CAGR of 3.8%. This growth can be attributed to the rising demand for precision cutting and manufacturing efficiency, essential for these sectors where high-quality standards and reliability are crucial.

In the automotive industry, the integration of plasma torches enhances manufacturing processes by allowing for improved welding and cutting capabilities, which streamline the production line. Concurrently, the aerospace sector is embracing plasma technology to facilitate the development of lightweight components, crucial for improving fuel efficiency and meeting stringent regulatory requirements. As industries push towards automation and advanced manufacturing techniques, the adoption of plasma torches is set to expand, driving future innovations and efficiency gains across these dynamic markets.

Case Studies: Successful Implementations of Plasma Torches in Diverse Industrial Applications

In recent years, plasma torches have gained significant traction across various industrial sectors due to their unmatched versatility and efficiency in handling complex tasks. One notable case study comes from the waste management industry, where plasma torches have been successfully implemented to convert hazardous waste into syngas—a valuable energy source. In this application, the high temperatures generated by plasma technology break down waste materials into their fundamental elements, effectively neutralizing toxins and reducing landfill volume while generating clean energy.

Another compelling example can be found in the metal fabrication industry. A leading automotive manufacturer adopted plasma torch cutting systems to enhance precision in their production line. The integration of this technology allowed for faster cutting speeds and cleaner edges, significantly improving the overall quality of metal components. The case study demonstrates how plasma torches not only streamline operations but also lead to substantial cost savings and reduced material waste, transforming traditional manufacturing processes for better efficiency. These examples illustrate the profound impact of plasma torch technology in driving innovation and sustainability across diverse industries.

Exploring Real World Applications of the Best Plasma Torch Across Diverse Industries

| Industry | Application | Benefits | Case Study Highlights |

|---|---|---|---|

| Manufacturing | Metal Cutting | High Precision and Speed | Reduced cycle times by 50% in automotive components. |

| Aerospace | Material Processing | Enhanced Material Integrity | Improved structural component reliability. |

| Construction | Surface Coating | Durable Finish | Extended lifespan of structures by 30%. |

| Shipbuilding | Welding and Cutting | Increased Efficiency | Reduced material waste and faster production times. |

| Automotive | Repair and Maintenance | Cost-Effectiveness | Lowered repair costs by 20% through efficient techniques. |

Analyzing Cost Benefits and ROI of Plasma Torch Adoption Across Key Industries

Adopting plasma torch technology offers significant cost benefits and ROI across various industries, particularly in manufacturing and metalworking. A recent analysis indicates that plasma cutting systems, known for their efficiency, can reduce material waste by nearly 25% and halve the cutting time compared to traditional methods. For manufacturers, this translates to reduced operational costs and increased output. According to industry experts, companies can expect an average ROI of up to 40% within the first year of investment due to these efficiency gains.

In addition to manufacturing, sectors such as automotive and aerospace are increasingly realizing the advantages of plasma torch technology. A study indicated that heavy industries adopting advanced plasma systems could see a drop in labor costs by up to 30% due to automation capabilities.

As industries pivot towards more sustainable practices, the integration of plasma torches can enhance both productivity and environmental responsibility, making it a pivotal investment for growth. Furthermore, as businesses aim to harness technological advancements, understanding the long-term financial impacts, including reduced energy consumption and maintenance costs, is crucial for decision-makers.

Future Trends: Innovations in Plasma Torch Technology and Their Implications for Industry 4.0

As industries continue to transition into the era of Industry 4.0, the role of innovative technologies like plasma torch systems becomes increasingly significant. These advancements not only enhance operational efficiency but also drive digital transformation across various sectors, including automotive and steel manufacturing. The future of plasma torch technology promises to revolutionize processes with improved precision, reduced waste, and increased automation.

In the automotive industry, digital transformation is propelled by automation, artificial intelligence, and the Internet of Things (IoT), which streamline production lines and improve overall quality. Implementing these technologies requires a strategic approach. Begin by assessing existing processes to identify areas for improvement. Integrating advanced data analytics can also yield insights into operational efficiencies, aiding in informed decision-making.

In steel manufacturing, trends such as sustainability and the adoption of smart factories are expected to shape the landscape by 2025. Companies must embrace these changes, considering partnerships with startups specializing in cutting-edge technologies. By fostering innovation and sustainability, they can position themselves as leaders in a rapidly evolving market. Emphasizing continuous learning and adaptation will be crucial for staying ahead in this dynamic environment.