Unlocking Precision: Technical Insights and User Guide for CNC Plasma Cutting Tables

In the ever-evolving landscape of metal fabrication, the use of CNC plasma cutting tables has emerged as a game-changer, revolutionizing the precision and efficiency of cutting processes. As industries increasingly adopt automation, the global CNC plasma cutting machine market is projected to grow at a CAGR of 5.6% from 2021 to 2026, reaching a value of $6 billion by the end of 2026 (Source: Market Research Future). This surge highlights the rising demand for high-quality, rapid cutting capabilities that CNC plasma cutting tables deliver. These advanced machines are designed to meet the rigorous standards of the aerospace, automotive, and construction sectors, where precision and productivity are paramount. In this blog, we delve into the technical insights and user guidance necessary to maximize the potential of CNC plasma cutting tables, ensuring that users can unlock their full capabilities and achieve remarkable results in their projects.

Understanding CNC Plasma Cutting Technology and Its Applications

CNC plasma cutting technology has become a cornerstone in modern manufacturing, enabling precise and efficient cutting for a wide array of materials. With the global CNC cutting machines market projected to reach USD 6,153.2 million by 2032, the demand for this technology is clearly on the rise. In particular, the CNC segment alone accounted for over USD 419.1 million in 2023 and is expected to grow to USD 722 million by 2032, indicating a robust growth trajectory fueled by advancements in automation and materials processing.

Recent innovations in this field are also noteworthy. For instance, an Iowa pipe fabricating shop has integrated water misting into its plasma cutting process, effectively eliminating the need for secondary grinding on stainless steel. This application not only enhances efficiency but also improves the quality of the cut surface. Additionally, emerging trends in digital cutting technology forecast a substantial market expansion from USD 2.5 billion in 2024 to USD 4.5 billion by 2033, achieving a CAGR of 7.5%. These developments showcase the versatility and expanding capabilities of CNC plasma cutting, making it an essential tool in various industries including automotive restoration, construction, and more.

Key Components of CNC Plasma Cutting Tables Explained

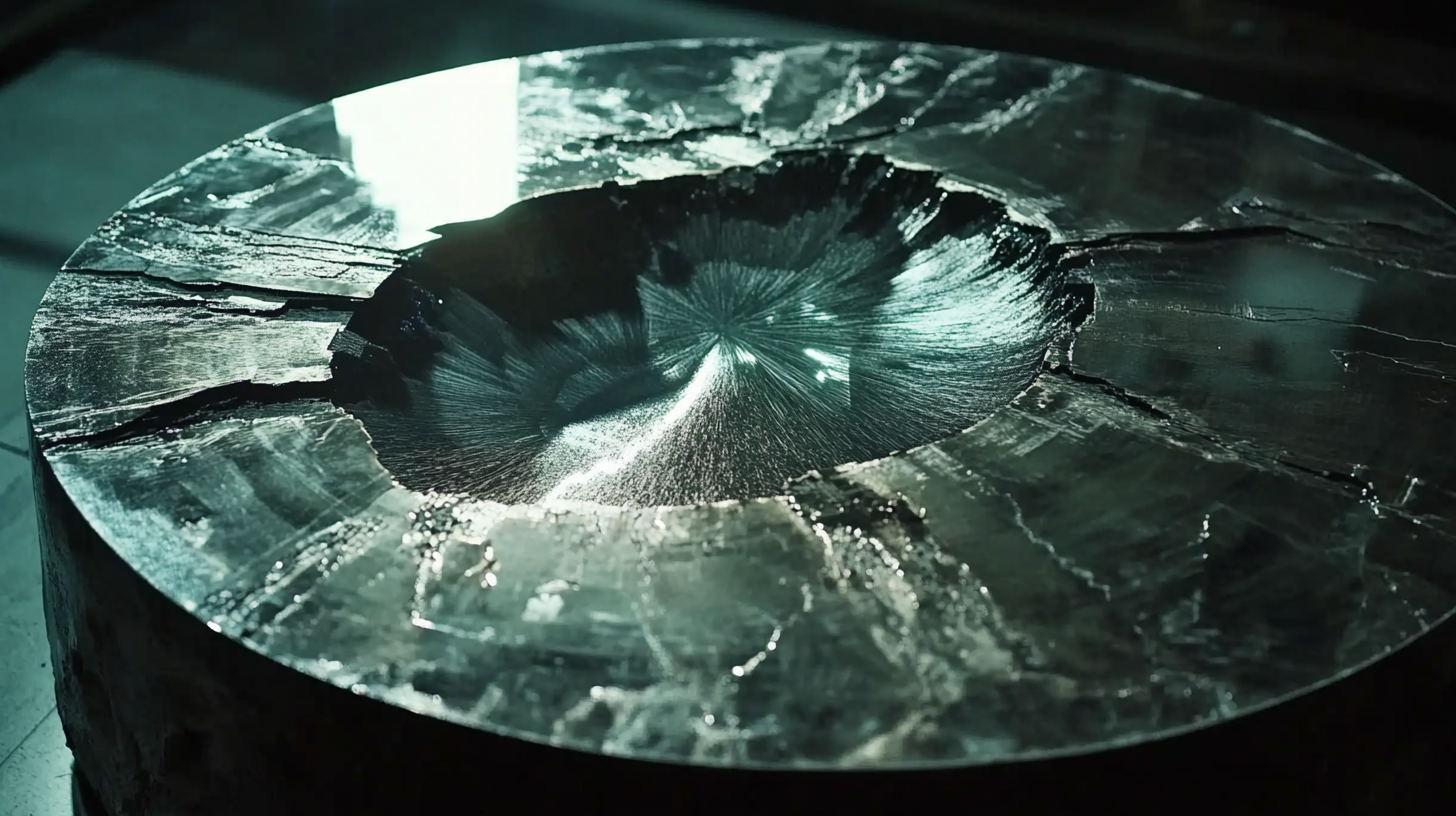

CNC plasma cutting tables are revolutionizing the metalworking industry by offering unmatched precision and efficiency. Understanding the key components of these machines is crucial for anyone interested in mechanized plasma cutting. At the heart of a CNC plasma cutting table is the control system, which directs the movement of the cutting torch with high accuracy. This system is often paired with advanced software that allows users to design complex patterns and shapes seamlessly. Additionally, the table itself is constructed to support a variety of materials, ensuring stability during the cutting process.

Another essential component is the plasma torch, which creates the heat necessary to melt the metal. The type of plasma torch used can significantly impact the quality of the cut, with options available for different power and thickness levels. Equally important is the table's surface, designed to minimize smoke and debris, enhancing visibility and safety during operation. By understanding these components, fabricators can make informed decisions that lead to smarter investments in their equipment, optimizing both performance and cost-effectiveness in their projects. This knowledge is especially beneficial for those working with tight budgets, as it allows for sophisticated operations without overspending.

Integrating Software with CNC Plasma Cutting for Optimal Performance

Integrating software effectively with CNC plasma cutting tables is crucial for achieving optimal performance in precision manufacturing. As the industry evolves, software solutions now offer features that enhance design, simulation, and cutting accuracy. Recent reports indicate that the global CNC software market is projected to reach $5.7 billion by 2026, driven by the demand for automation and precision in manufacturing processes. Companies are increasingly adopting design programs and G-code simulation tools to streamline their workflows, resulting in improved turnaround times and reduced material waste.

The rise of artificial intelligence in CNC machining represents a significant shift towards smarter manufacturing practices. AI enhances capabilities by analyzing performance data and optimizing cutting paths, thus ensuring higher precision and efficiency. Moreover, advancements in laser profile scanners showcase how technology is being utilized to achieve better production quality. These lightweight, compact scanners integrate smoothly with CNC systems, providing real-time feedback that aids in maintaining precision during cutting processes. As businesses seek to innovate and adapt to market demands, the integration of advanced software and AI-driven solutions becomes pivotal in enhancing productivity and operational excellence.

Tips for Maintenance and Troubleshooting of Plasma Cutting Tables

CNC plasma cutting tables are invaluable tools in manufacturing, offering precision and efficiency in metal fabrication. However, like any machinery, they require regular maintenance and troubleshooting to ensure optimal performance. According to a report by the Fabricators & Manufacturers Association, approximately 40% of CNC machine downtime is attributed to maintenance issues. Understanding how to maintain your plasma cutting table can significantly reduce this downtime and enhance productivity.

One essential tip for maintenance is to regularly inspect and replace wear parts, such as nozzles and electrodes, as these directly affect the cutting quality. It's recommended to perform this inspection after every 25 hours of operation. Additionally, keeping the plasma cutting table clean from debris and slag can prevent potential damage and enhance the machine’s longevity. Regularly checking gas flow and pressure can also help ensure a consistent cut, as fluctuations can lead to poor-quality edges.

In the event of troubleshooting, a key tip is to check the cutter's settings and parameters. According to industry standards, many cutting issues stem from incorrect speed or power settings. Additionally, ensure that there are no obstructions in the torch path, which can lead to inconsistent cuts. By adhering to these maintenance and troubleshooting tips, operators can maximize the lifespan and efficiency of their CNC plasma cutting machines.

Enhancing Precision: Best Practices for CNC Plasma Cutting Projects

When working with CNC plasma cutting tables, precision is paramount. Achieving optimal results requires not only the right equipment but also the application of best practices throughout the cutting process. One fundamental tip is to ensure that your table is properly calibrated. Misalignment can lead to uneven cuts, so regular checks and adjustments are vital for maintaining accuracy over time.

Another critical aspect is selecting the appropriate parameters for your material. Factors like cutting speed, amperage, and gas mixture can significantly affect the quality of the cut. Always refer to the manufacturer's recommendations and perform test cuts on scrap material to hone in on the perfect settings. This iterative approach allows for fine-tuning that can greatly enhance final outcomes.

Lastly, maintain a clean work area and torch. Contaminants on the surface or nozzle can adversely affect the cut quality. Incorporating a routine cleaning schedule into your workflow ensures that your equipment performs at its best, reducing downtime and enhancing productivity. By implementing these best practices, you’ll not only improve the precision of your CNC plasma cutting projects but also extend the lifespan of your machinery.

Unlocking Precision: Technical Insights and User Guide for CNC Plasma Cutting Tables

| Aspect | Description | Best Practices | Common Issues |

|---|---|---|---|

| Material Selection | Choosing the right material can greatly impact the cutting quality. | Use materials compatible with your plasma cutting thickness specs. | Using materials too thick or too thin for the machine's capability. |

| Settings Optimization | Optimizing speed and amperage can improve cut quality. | Regularly calibrate machine settings based on material thickness. | Inadequate setting adjustments leading to excessive dross. |

| Torch Maintenance | Regular maintenance ensures consistent performance. | Check and replace consumables based on usage. | Worn out torches causing uneven cuts. |

| Software Configuration | Proper software setup enhances the cutting process. | Ensure software parameters align with material specifications. | Mismatched software settings leading to inaccurate cuts. |

| Safety Precautions | Following safety measures prevents accidents. | Wear appropriate personal protective equipment (PPE). | Neglecting safety can lead to severe injuries. |