The Future of Cutting Edge Technology Exploring the Wonders of Plasma Torch

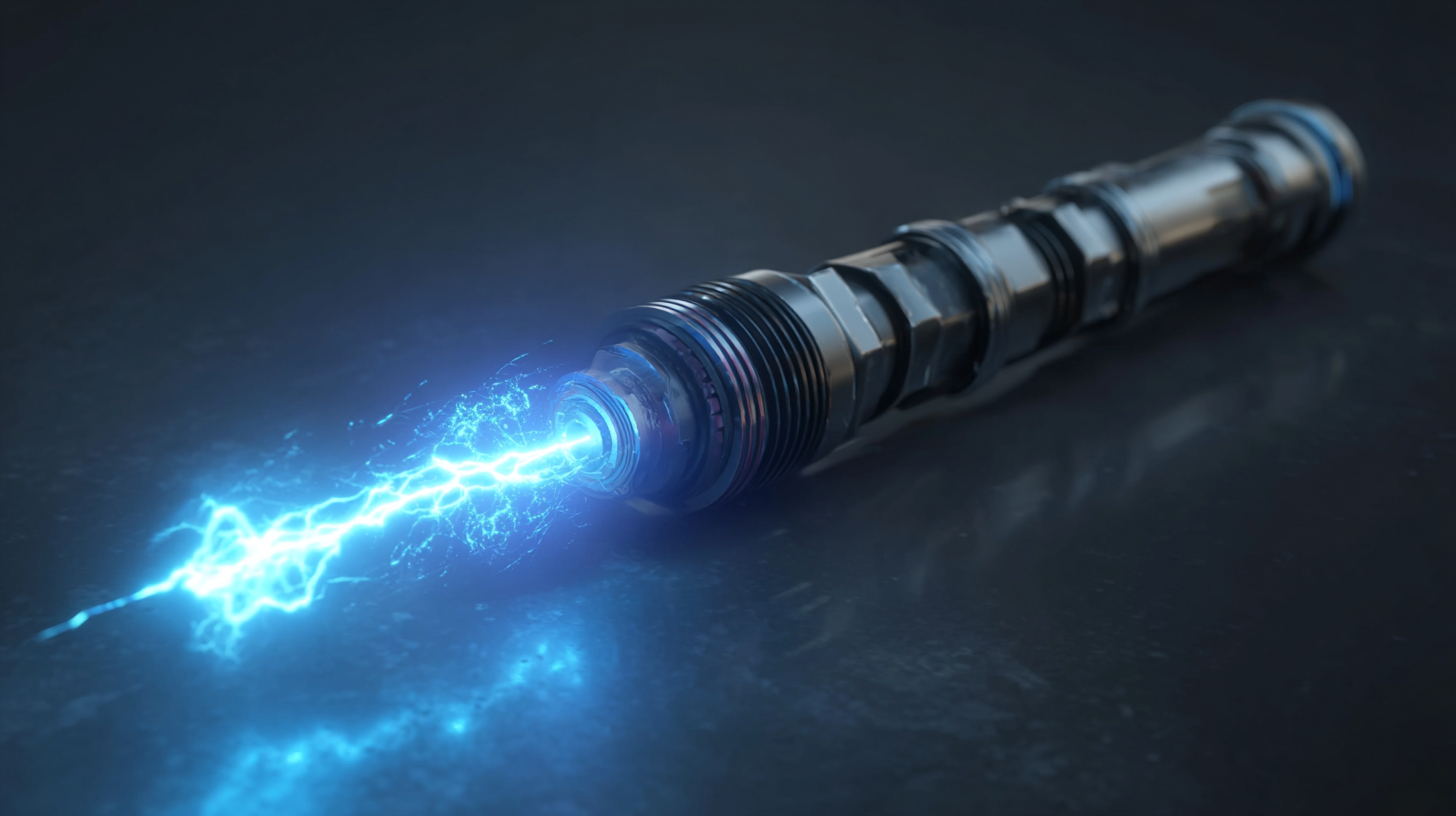

The advent of advanced technologies has significantly transformed various industries, enabling more efficient processes and innovative applications. Among these breakthroughs, the Plasma Torch stands out as a revolutionary tool, harnessing the power of ionized gas to cut through materials with precision and speed.

According to a report by MarketsandMarkets, the global plasma torch market is projected to reach USD 2.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5% from 2020. This surge in demand is driven by the increasing need for high-quality, low-cost manufacturing processes in sectors such as automotive, aerospace, and metal fabrication.

As we delve into the wonders of Plasma Torch technology, we will explore its applications, advantages, and future potential in shaping the industries of tomorrow, paving the way for smarter, cleaner, and more efficient production methods.

Overview of Plasma Torch Technology and Its Applications

Plasma torch technology is an innovative and transformative development that harnesses the power of plasma—a state of matter similar to gas but consisting of charged particles. This technology generates extremely high temperatures, allowing it to cut, weld, and solidify various materials with precision and efficiency. The versatility of plasma torches makes them indispensable in numerous industries, including manufacturing, metalworking, and waste management. For instance, in metal cutting, plasma torches can achieve intricate designs and seamless cuts, significantly improving productivity and reducing material waste.

Plasma torch technology is an innovative and transformative development that harnesses the power of plasma—a state of matter similar to gas but consisting of charged particles. This technology generates extremely high temperatures, allowing it to cut, weld, and solidify various materials with precision and efficiency. The versatility of plasma torches makes them indispensable in numerous industries, including manufacturing, metalworking, and waste management. For instance, in metal cutting, plasma torches can achieve intricate designs and seamless cuts, significantly improving productivity and reducing material waste.

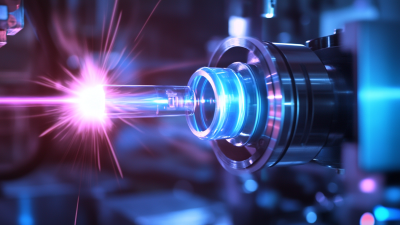

Beyond cutting and welding, plasma torch technology has shown promise in environmental applications, such as waste treatment and disposal. By using plasma to convert organic waste into syngas—a useful energy source—companies can effectively manage waste while simultaneously generating energy. Additionally, plasma torches are being explored in aerospace and automotive industries for surface treatment and coating processes, enhancing the durability and performance of components. This wide array of applications showcases the profound impact of plasma torch technology, paving the way for future innovations and advancements in various fields.

The Science Behind Plasma Formation and Its Unique Properties

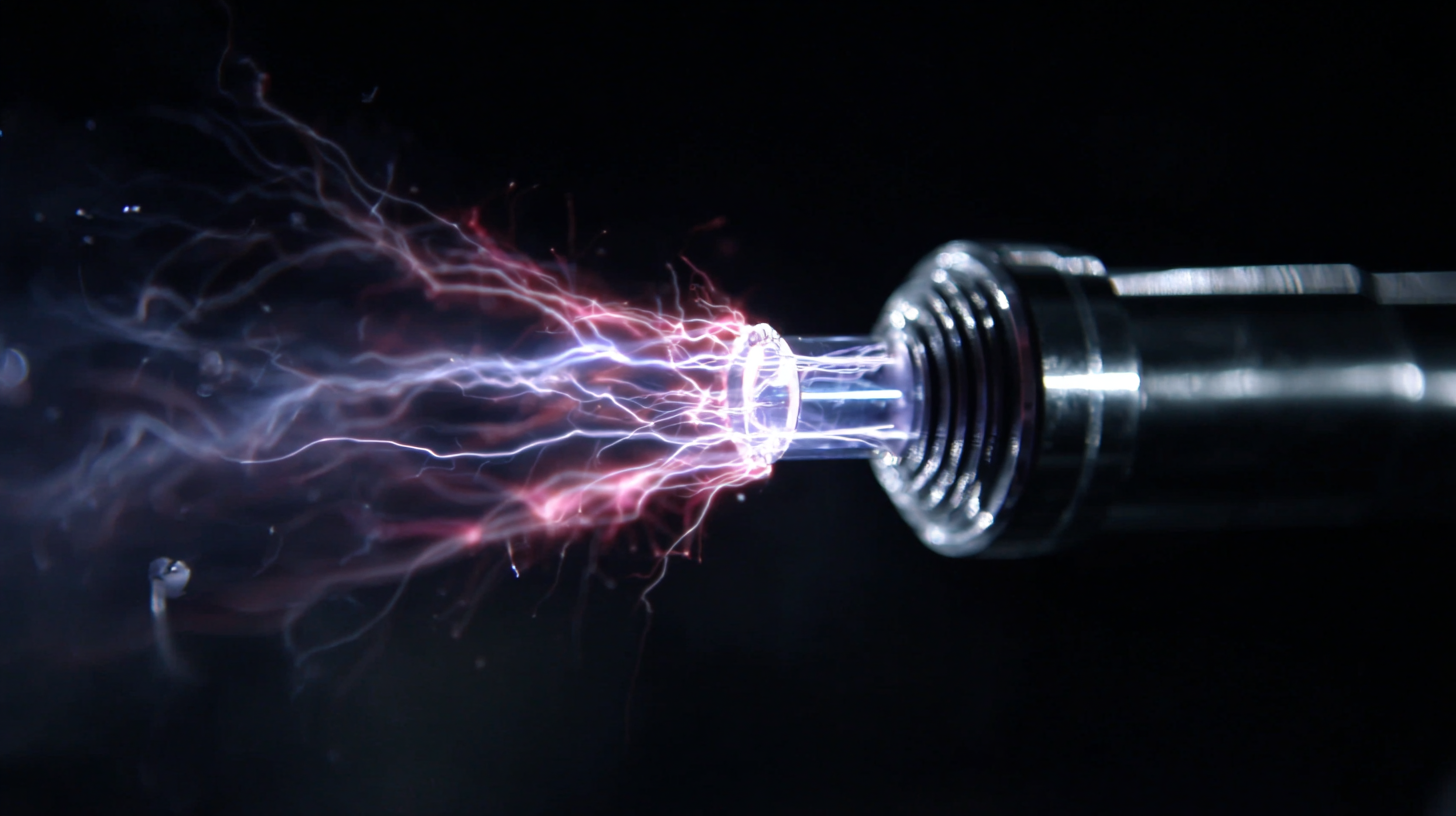

Plasma torches represent a pinnacle of technological advancement, leveraging the unique properties of plasma – a state of matter formed by ionizing gas. When energy is introduced into a gas, it can strip electrons from atoms, creating a mix of ions and free electrons. This process allows plasma torches to reach temperatures exceeding 28,000 degrees Fahrenheit, making them ideal for applications that require precise cutting or welding. According to a report by Research and Markets, the global plasma arc welding market is projected to grow at a CAGR of 5.5% through 2026, showcasing the increasing significance of this technology in various industries.

The unique characteristics of plasma, including high thermal energy and excellent conductivity, also facilitate its use in material processing. Plasma can effectively melt or vaporize metals, reducing the thermal distortion commonly seen with traditional cutting methods. According to a study published by the Journal of Materials Processing Technology, plasma cutting can improve efficiency by 30% compared to conventional cutting methods, indicating substantial advancements in manufacturing processes. As industries seek more sustainable and versatile solutions, understanding the science behind plasma formation will be crucial in harnessing its potential for future applications.

Innovative Uses of Plasma Torch in Industry and Medicine

The plasma torch technology is revolutionizing various industries, particularly in medicine and manufacturing. Its application in sterilization processes is notably growing, with the plasma sterilizer market projected to reach approximately $1.188 billion by 2033, showcasing a compound annual growth rate (CAGR) of 5.88%. This advanced technology offers a safe and effective method for sterilizing medical instruments and equipment, ensuring patient safety and reducing infection rates.

Furthermore, the demand for plasma systems extends into semiconductor manufacturing and surface treatment applications. The global plasma surface treatment equipment market is expected to increase significantly, from $394 million in 2025 to $576 million by 2032, reflecting a robust CAGR of 5.6%. The ability of plasma technologies to precisely control energy and enhance material properties makes them invaluable in producing high-quality components in automotive and electronic industries. As these sectors adapt to innovative processes, the role of plasma torch technology will continue to expand, paving the way for future advancements in sustainable manufacturing practices and medical applications.

The Future of Cutting Edge Technology: Exploring the Wonders of Plasma Torch - Innovative Uses of Plasma Torch in Industry and Medicine

| Application Area | Industrial Use | Medical Use | Advantages |

|---|---|---|---|

| Material Processing | Cutting, welding, and surface treatment of metals | Sterilization of surgical instruments | High precision, minimal thermal distortion |

| Waste Management | Plasma gasification for waste conversion | Treatment of hazardous medical waste | Reduces volume and toxicity of waste |

| Electrical Engineering | Plasma cutting in electronic component manufacturing | Plasma surgery for minimally invasive procedures | Improved efficiency and reduced operational costs |

| Research and Development | Prototype development using advanced materials | Regenerative medicine applications | Innovative tool for scientific exploration |

Future Trends and Developments in Plasma Technology

The rapid advancements in plasma technology are set to revolutionize various industries, heralding a new era of efficiency and precision. Plasma torches, which utilize ionized gas to generate intense heat, are leading the charge in applications ranging from metal cutting and welding to waste management and material synthesis. As researchers continue to explore the potential of plasma, we can expect major developments that will enhance performance, reduce operational costs, and minimize environmental impact.

One of the most exciting future trends in plasma technology is its integration with renewable energy sources. This synergy could enable plasma systems to operate more sustainably, utilizing energy from solar, wind, or other clean sources. Additionally, innovations in plasma diagnostics and control systems are expected to improve the accuracy and versatility of these tools, allowing them to perform complex tasks with minimal human intervention. As the technology matures, industries like aerospace, automotive, and healthcare could benefit significantly from plasma-assisted processes, paving the way for breakthroughs that were previously unimaginable.

Challenges and Considerations in Advancing Plasma Torch Systems

As plasma torch technology evolves, several challenges and considerations must be addressed to maximize its potential. One significant hurdle is the efficiency of plasma generation and maintenance. Effective cooling systems and advanced materials are crucial to enhance the performance and lifespan of plasma torches. Researchers are exploring innovative designs to optimize energy consumption while ensuring that the plasma remains stable and controllable during operations.

Tip: Investing in ongoing research and development can pave the way for breakthroughs in plasma torch technology. Collaborating with interdisciplinary teams can foster innovative solutions and overcome technical obstacles.

Another vital consideration is the safety and environmental impact of utilizing plasma torches in various applications. Ensuring proper safety protocols and waste management strategies is essential to mitigate risks associated with high-temperature processes and the materials involved. Additionally, embracing sustainable practices will be pivotal as industries increasingly prioritize eco-friendly technologies.

Tip: Regular training and education for operators on safety measures and environmental guidelines can significantly reduce risks and enhance operational efficiency in plasma torch applications.

Related Posts

-

Exploring Real World Applications of the Best Plasma Torch Across Diverse Industries

-

Ultimate Guide to Choosing the Best Plasma Torch for Your Welding Needs

-

What Makes the Best Plasma Machine Stand Out in Precision Cutting Technology

-

Choosing the Right Manufacturer for the Best Plasma Cutting Machine Insights and Key Data

-

Navigating 2025's Cutting-Edge CNC Innovations: Proven Strategies to Optimize Your Best CNC Cutter Investments

-

Mastering the Art of Plasma Cutting with the Best Plasma Cutter Guide