Top 5 Injection Molding Machines With Robots Explained

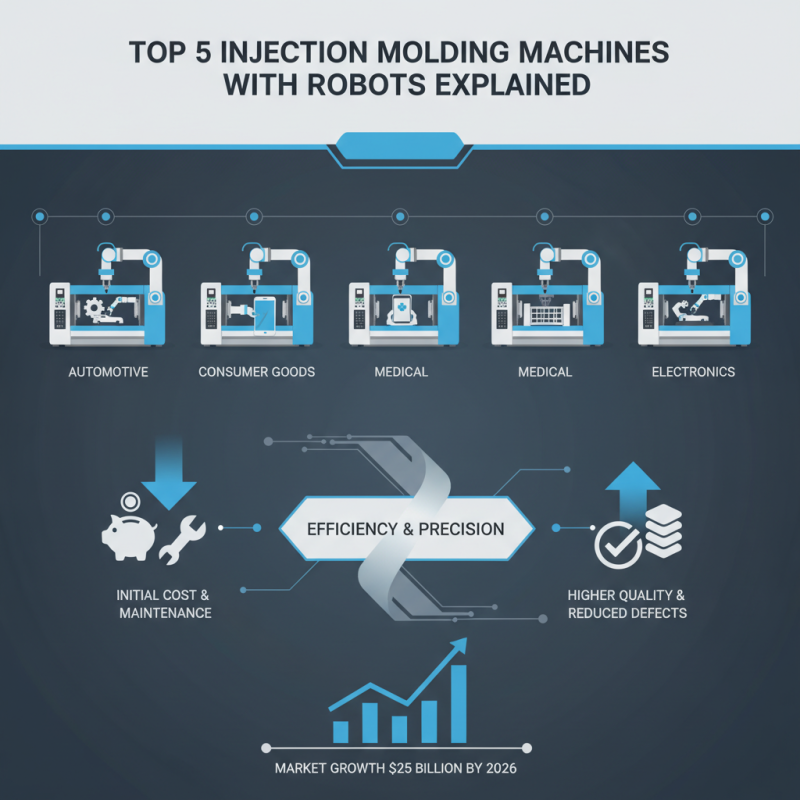

In the rapidly evolving world of manufacturing, the integration of "Injection Molding Machine With Robot" technology is becoming increasingly important. According to a recent report by ResearchAndMarkets, the global injection molding machinery market is projected to reach $25 billion by 2026, driven by the demand for more efficient production processes. The synergy of robots with injection molding machines enhances precision and reduces cycle times, making them vital in industries like automotive and consumer goods.

However, data also points to a challenge: the initial cost of integrating robotic systems can deter smaller manufacturers. While the long-term benefits may outweigh these costs, many companies still hesitate. Moreover, as technology advances, keeping up with maintenance and updates can prove daunting. The details matter—an outdated robot may not effectively complement a new injection molding machine, possibly hindering production efficiency.

Despite these hurdles, the benefits of combining robotics with injection molding are significant. Enhanced automation can lead to higher quality products and fewer defects. As we explore the top five injection molding machines equipped with robotic systems, it’s essential to consider these complexities and the broader implications for the manufacturing sector.

Overview of Injection Molding Machines and Their Importance in Manufacturing

Injection molding machines play a pivotal role in modern manufacturing. They are the backbone of producing plastic components across various industries. According to recent reports, the global injection molding market is expected to reach $20 billion by 2026. This growth stems from the increasing demand for lightweight, durable materials in automotive and consumer goods.

Robots integrated with these machines enhance efficiency and precision. They automate the handling of molded parts, reducing human error and increasing production speed. A study found that automation in manufacturing can improve efficiency by up to 30%. Yet, not every facility fully utilizes this technology. Many struggle to find the right balance between automation and manual processes, leading to operational inconsistencies.

Moreover, the environmental impact of injection molding is a concern. The process generates waste and can produce significant energy consumption. Industry reports indicate that optimizing energy use could reduce manufacturing costs by 15%. There is still room for improvement in sustainable practices within the industry. Striking the right balance between productivity and environmental responsibility is an ongoing challenge for manufacturers today.

Key Features to Look for in Injection Molding Machines with Robots

When selecting an injection molding machine with robots, it is crucial to consider several key features. Automation integration is vital. Machines equipped with robotic arms increase efficiency and reduce labor costs. Data shows that automated systems can improve production rates by 25-40%.

Another important aspect is the adaptability of the machine. Flexibility in handling different materials and sizes is necessary. Some advanced models can switch between thermoplastics and thermosets seamlessly. This versatility allows manufacturers to respond to market demands quickly. However, not all machines offer this capability. Assessing the range of materials supported can reveal potential limitations.

Users should also evaluate the machine's energy efficiency. The trend is toward more sustainable operations. According to industry reports, energy-efficient machines can cut consumption by up to 30%. This not only lowers costs but also aligns with environmental goals. Yet, continuous monitoring is essential because inefficiencies may arise over time. Balancing features like speed, flexibility, and energy use can be challenging. It requires careful consideration to avoid common pitfalls in production processes.

Top 5 Injection Molding Machines Integrated with Robotic Technology

The integration of robotic technology into injection molding machines is revolutionizing the industry. According to a recent market report, over 60% of manufacturers are adopting automation to improve efficiency. Robotic arms are often used to handle tasks like part removal and packaging. This technology can operate 24/7, increasing production rates significantly.

However, the transition is not without challenges. Some manufacturers struggle with the high initial costs of robotic systems. An estimated 30% report difficulties in training staff to manage these advanced machines. Additionally, the risk of equipment malfunction can disrupt production. Regular maintenance and updates are crucial, yet often overlooked.

While the benefits are clear, the implementation process needs careful planning. Companies must assess specific needs. Investing in tailored robotic solutions could yield better ROI. The right technology can streamline operations, but it's important to acknowledge potential pitfalls. Addressing these issues can lead to optimal integration of robotic systems in injection molding.

Comparative Analysis of Performance and Efficiency of Each Machine

When evaluating the performance and efficiency of injection molding machines integrated with robots, data reveals significant differences. A recent industry report indicates that machines equipped with robotic arms can reduce cycle time by up to 30%. This efficiency stems from the robots’ ability to handle cooling, part retrieval, and packaging simultaneously. In contrast, traditional systems often struggle with these tasks.

Energy consumption also plays a critical role in the comparative analysis. Advanced machines with robotics typically consume 10-20% less energy per cycle. A study from a leading manufacturing research group shows that energy-efficient systems can save facilities over $50,000 annually. However, some machines still lack optimal energy management features. Reacting promptly to these inefficiencies can improve the overall production output.

One area for reflection is the maintenance of these systems. While robotic integration offers multiple benefits, it raises the complexity of maintenance protocols. Technicians may require specialized training, which can lead to downtime. The balance between advanced automation and ease of maintenance is not straightforward. Understanding this trade-off becomes vital for manufacturers aiming to maximize productivity while minimizing disruptions.

Future Trends in Injection Molding and Robotics Integration

The future of injection molding and robotics integration is rapidly evolving. As manufacturing processes become more automated, the role of robots in injection molding is gaining significant momentum. Traditional methods often required manual labor, which is prone to errors. Now, we are witnessing robots performing intricate tasks with precision. These robots handle everything from loading materials to unloading finished products. This shift not only reduces labor costs but also improves overall efficiency.

However, the integration of robotics is not without its challenges. Technicians must adapt to new systems and technologies. Training is essential for staff to effectively work alongside automated machines. Issues may arise when machines encounter unexpected variables. Addressing these gaps is crucial for smooth operations. Furthermore, the initial investment in robotic technology can be daunting for smaller manufacturers. They may hesitate, fearing that returns won’t justify the costs.

Yet, the benefits often outweigh these concerns. Enhanced productivity and consistent quality are significant advantages. The industry is moving towards smarter systems that use data analytics. Predictive maintenance will reduce downtime. The integration of AI will allow for more intuitive operations, making the future exciting. Robotics and injection molding are set to redefine manufacturing.