Top 5 Plastic Injection Mold Techniques You Must Know?

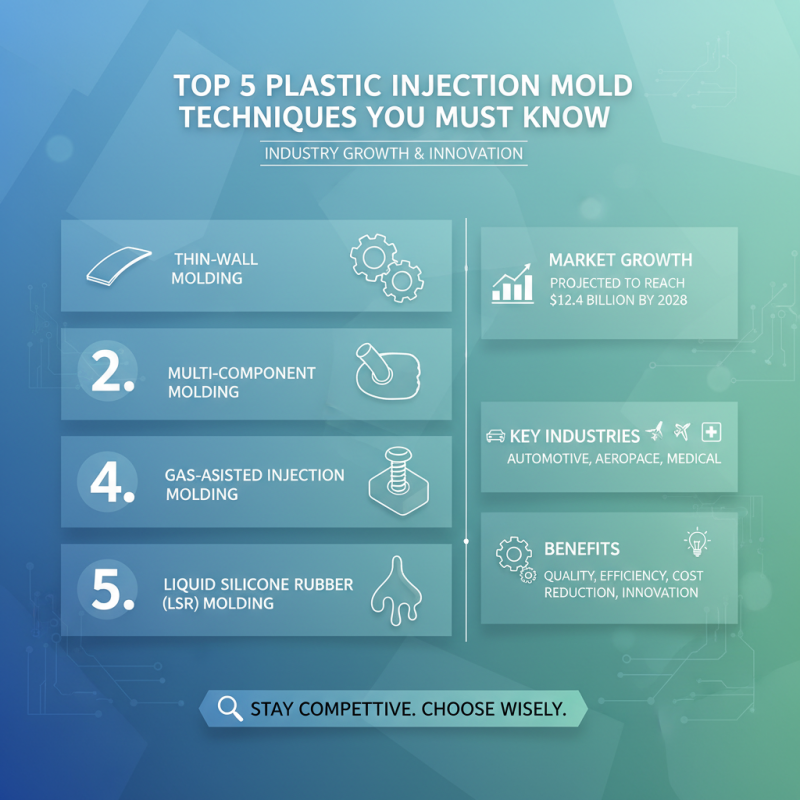

The Plastic Injection Mold industry is thriving. According to a market report by Grand View Research, it is projected to reach $12.4 billion by 2028. This growth showcases the rising demand for precision-engineered plastic components across various sectors. The automotive, aerospace, and medical industries are significant contributors to this trend.

Understanding plastic injection mold techniques is essential. These techniques influence quality, efficiency, and costs. However, many manufacturers overlook the importance of selecting the right method. Traditional methods may seem adequate, but they often fall short in innovation and adaptability. Companies must reconsider their approaches to stay competitive.

Mistakes in mold design can lead to costly delays. These issues often stem from inadequate planning or failure to adopt advanced techniques. Emphasizing the right processes can significantly enhance productivity. By focusing on key injection molding techniques, manufacturers can address common challenges. Awareness of trends and technologies is vital to thrive in this competitive landscape.

Overview of Plastic Injection Molding and Its Importance

Plastic injection molding has transformed manufacturing, making it crucial for various industries. In 2022, the global market for plastic injection molding reached approximately $280 billion, reflecting its rising demand. This technique is essential for producing high-precision parts across automotive, healthcare, and consumer goods sectors. Each of these industries relies on consistent quality and efficiency, achievable through advanced molding processes.

Moreover, the injection molding process reduces waste and optimizes material usage. A recent study noted that injection molding can minimize scrap rates down to 3%, showcasing its efficiency. However, the process isn't without challenges. Issues like cycle time, temperature control, and material choice can impact quality. For instance, improper temperature management can lead to defects, such as warping or uneven surfaces. These factors necessitate a thorough understanding of the process and continuous improvements.

In an era where sustainability is paramount, plastic injection molding also raises questions. While it often promotes recycling, the environmental impact of plastics remains a concern. Finding a balance between efficient production and ecological responsibility is essential. As the industry evolves, addressing these challenges will be crucial for long-term success and sustainability.

Understanding the Basics of Plastic Injection Mold Techniques

Plastic injection molding is a crucial technique in manufacturing. It involves injecting molten plastic into a mold cavity. This process creates various parts and products used in everyday life. Understanding the basics helps you appreciate its application and significance.

Different techniques exist within plastic injection molding. Hot runner systems, for example, reduce waste and improve efficiency. However, they can be costly and complex to set up. Another method is gas-assisted injection, which uses gas to create hollow sections in parts. This technique can save material but may require fine-tuning. Each method has its pros and cons, and careful consideration is necessary.

Mastering these techniques is not just about efficiency. It requires a keen eye for detail. Even experienced professionals encounter challenges. For instance, achieving the desired surface finish might take multiple attempts. Testing and adjustments are vital for success. Being aware of these challenges helps in refining your approach and improving outcomes.

Top 5 Essential Plastic Injection Mold Techniques Explained

Plastic injection molding is a critical process in manufacturing. Understanding key techniques can significantly enhance production quality. One vital technique is the use of multi-cavity molds. They allow multiple parts to be produced simultaneously, boosting efficiency. According to a report by Global Market Insights, the market for multi-cavity molds is projected to reach $9 billion by 2026, highlighting their significance in cost-effective production.

Another essential method is gas-assisted injection molding. This technique introduces gas into the molten plastic to create hollow sections. It reduces material usage and cycle times. Research from the Society of Plastics Engineers suggests that gas-assisted molds can decrease production costs by up to 20%. However, there’s a learning curve in mastering this technique, often leading to initial setbacks.

Additionally, hot runner systems can optimize the injection process. They keep the plastic in a molten state within the runner system, resulting in less waste. An industry study indicates that hot runner technology can save manufacturers around $44,000 in raw materials annually. Yet, the complexity of these systems can pose challenges in maintenance. Keeping a balance between efficiency and difficulties is key for many manufacturers in the field.

Step-by-Step Process of Each Injection Mold Technique

Plastic injection molding is a key technique in manufacturing. Understanding the step-by-step process of each method is crucial for success. Let’s dive into the details of some popular injection mold techniques.

Thermoplastic injection molding is quite common. It begins with heating plastic pellets until they melt. Once melted, the liquid is injected into a mold. The cooling process solidifies the plastic, forming the desired shape. Care must be taken to avoid defects like warping or incomplete filling. The margin for error can be narrow, requiring precision and attention.

Another technique is compression molding. This method uses heat and pressure to shape materials. First, the material is preheated and placed in a mold cavity. Then, it's pressed using a top plate. This process can lead to inconsistent results if not monitored closely. It’s essential to adjust the temperature and pressure appropriately. Improper settings can result in defects or inconsistent part quality.

Each molding technique offers distinct benefits and challenges. The step-by-step processes may seem straightforward, yet they demand careful management. Continuous improvement and learning from mistakes are vital in achieving great results in plastic injection molding production.

Top 5 Plastic Injection Mold Techniques You Must Know

| Technique | Description | Advantages | Disadvantages | Application |

|---|---|---|---|---|

| Standard Injection Molding | A common process for creating plastic parts by injecting molten material into a mold. | High efficiency, good surface finish, and complex shapes are achievable. | High initial costs and limited to thermoplastics. | Toys, automotive parts, and household items. |

| Multi-Cavity Injection Molding | Involves multiple molds in a single injection unit to produce several identical parts simultaneously. | Increased production rates and lower costs per unit. | More complex mold design and higher initial costs. | High volume production for consumer products. |

| Gas-Assisted Injection Molding | Uses gas to create hollow parts, reducing material usage and weight. | Lighter parts and reduced waste material compared to traditional methods. | More complex equipment and potential for inconsistent quality. | Automotive and appliance parts. |

| Insert Injection Molding | Involves inserting metal or other materials into the mold before injecting plastic. | Enhanced strength and durability of the final product. | Higher complexity and cost of inserts. | Electronics and automotive components. |

| Rotational Molding | Rotates the mold to evenly coat the interior with plastic, creating hollow objects. | No seams, good for large parts. | Slower production rates and limited to certain shapes. | Tanks, containers, and playground equipment. |

Choosing the Right Technique for Your Plastic Injection Needs

When choosing the right injection molding technique, it’s essential to consider your specific needs. Different techniques work best for various materials and product designs. The right choice can save time and money, while a poor decision may lead to defects and increased costs.

Tips: Always evaluate the complexity of your product design. Simpler designs can often utilize standard techniques effectively. However, complex shapes may require advanced techniques, which can increase processing time.

Material selection is crucial. Some techniques work better with specific plastics. For example, thermoplastic materials often yield higher flexibility, while thermosetting plastics offer better durability.

Tips: Prototype your designs before finalizing. This allows for assessment of the chosen technique’s effectiveness. Testing can reveal hidden flaws in both design and process.

Be mindful of production volume as well. High-volume production may necessitate techniques that offer faster cycle times. In contrast, lower volumes may benefit from cheaper, more straightforward methods.

Adjust your approach based on feedback from your prototypes and tests. This reflection can lead to significant improvements and successfully guide you in your selection process.