Unlock Your Creative Potential: How a CNC Plasma Table Kit Revolutionizes Metalworking Projects

In today's fast-paced world, creativity and innovation are paramount in the realm of metalworking projects. The emergence of advanced tools like the CNC Plasma Table Kit has revolutionized how creators approach their designs and fabrication processes. By combining precision engineering with user-friendly functionalities, this kit empowers both seasoned professionals and enthusiastic hobbyists to unlock their full creative potential.

Understanding CNC Plasma Table Technology for Metalworking Mastery

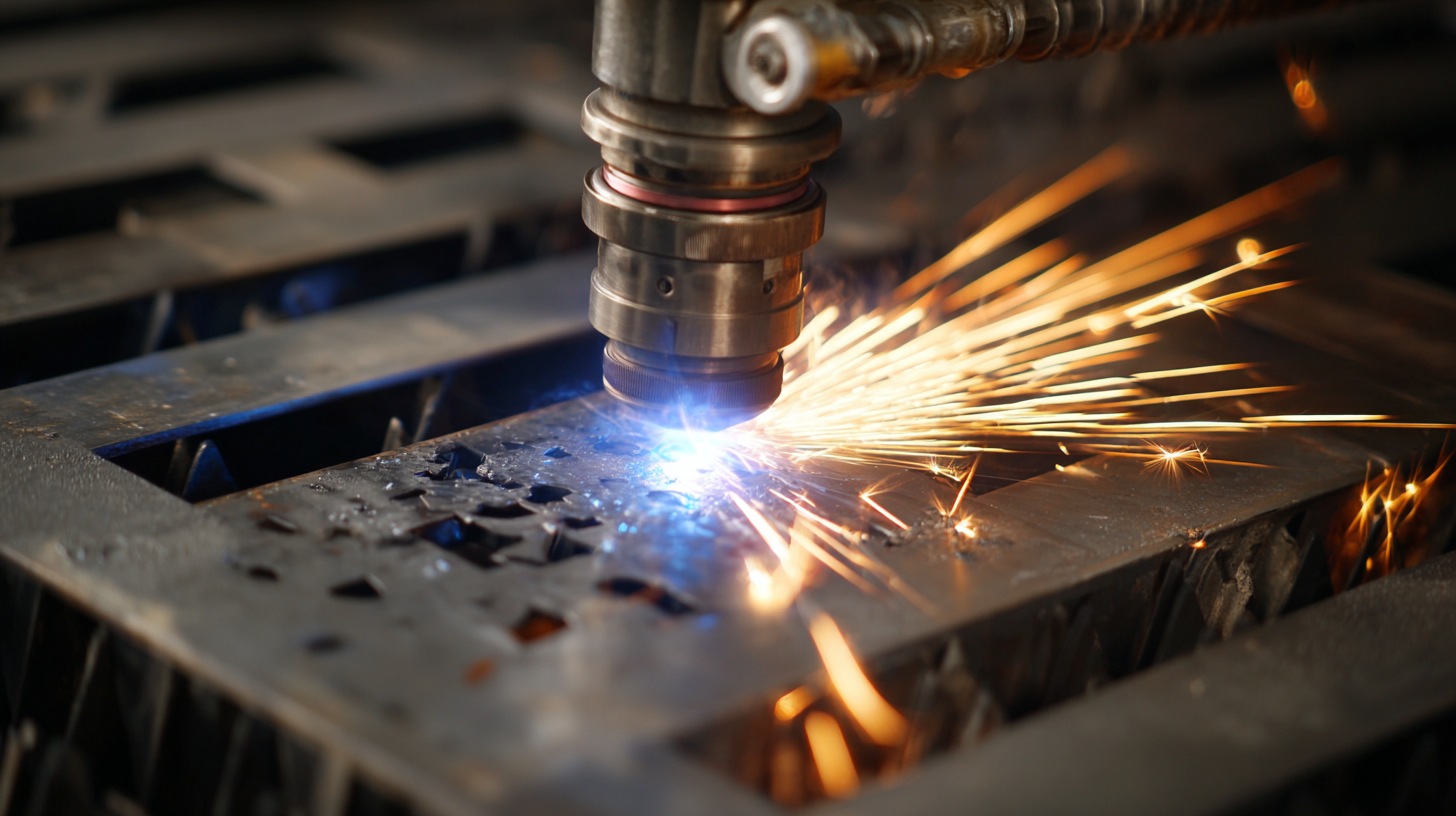

CNC plasma table technology has emerged as a groundbreaking tool in the realm of metalworking, offering unparalleled precision and creativity for makers and craftsmen alike. By understanding the mechanics behind CNC plasma tables, metalworkers can transform their projects, turning raw metal sheets into intricate designs with ease. This technology not only enhances the quality of work but also significantly reduces production time, allowing artists to focus more on refining their craft rather than on manual processes.

The ability to create detailed patterns and components opens up a world of possibilities, whether one is a seasoned blacksmith or a hobbyist just starting with a home forge kit. As metalworking enthusiasts explore this technology, they find themselves equipped to tackle more ambitious projects, from decorative items to functional tools. By integrating CNC plasma cutting into their workflow, metalworkers can elevate their craft, mastering techniques that were once restricted to professional workshops, thus revolutionizing their approach to metalworking artistry.

Unlock Your Creative Potential: CNC Plasma Table Technology

This chart illustrates the versatility of different metal thicknesses suitable for CNC plasma cutting and their corresponding applications in metalworking projects.

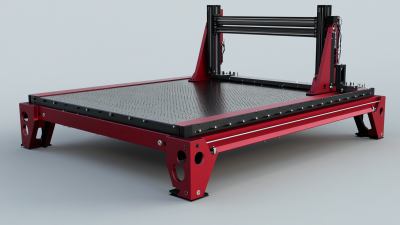

Essential Features to Look for in a CNC Plasma Table Kit

When selecting a CNC plasma table kit, understanding the essential features can significantly enhance your metalworking projects. A crucial aspect to consider is the cutting precision. According to a report by Grand View Research, the CNC machine market is expected to reach USD 100 billion by 2025, driven largely by advancements in cutting technologies. High-quality CNC plasma tables often come equipped with advanced motion control systems and integrated software that ensures consistently accurate cuts, which is vital for intricate designs.

Additionally, the versatility of the kit plays a pivotal role in its effectiveness. A comprehensive study published by IBISWorld highlights that businesses employing CNC technology can improve productivity by as much as 30%. Look for kits that offer adjustable cutting speeds and a variety of compatible materials, allowing for projects ranging from detailed artwork to structural components. Moreover, features such as easy setup and maintenance can not only save time but also elevate the overall efficiency of your production processes. Investing in a CNC plasma table that ticks all these boxes sets the stage for a truly transformative metalworking experience.

Unlock Your Creative Potential: How a CNC Plasma Table Kit Revolutionizes Metalworking Projects - Essential Features to Look for in a CNC Plasma Table Kit

| Feature | Description | Importance Level |

|---|---|---|

| Cutting Speed | The maximum speed at which the CNC plasma table can operate, influencing production time. | High |

| Table Size | The dimensions of the table, which determine the size of the materials that can be machined. | Medium |

| Software Compatibility | The ability of the CNC plasma table to work with various design software that you prefer. | High |

| Precision | The accuracy of cuts made by the CNC plasma table, affecting the quality of finished products. | High |

| Portability | How easily the CNC plasma table can be moved or transported to different locations. | Medium |

| Power Supply | The voltage and type of power supply required for the CNC plasma table to operate effectively. | Medium |

Step-by-Step Guide to Setting Up Your CNC Plasma Table

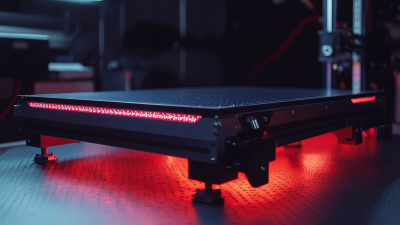

Setting up a CNC plasma table can significantly enhance your metalworking projects, unlocking potential that traditional methods can't match. As the CNC industry grows — with companies targeting 30-35% growth over the next few years — the accessibility of such technology is becoming more pronounced. Reports indicate that advancements in CNC machinery are enabling manufacturers to achieve up to 90% capacity utilization, demonstrating the rising demand for precision technology in the market.

For hobbyists and small business owners, a CNC plasma table kit provides an affordable means to elevate craftsmanship. Recent developments highlight portable CNC machines that make professional-grade capabilities accessible to everyone. This aligns with the trend toward greater efficiency in manufacturing processes, as the latest innovations focus on enhancing dimensional measurement and real-time metrology.

With such tools, even those working in remote areas can produce high-quality, production-ready parts, revolutionizing the way metalworking projects are approached. Setting up your own CNC plasma table can serve as a pivotal step towards transforming DIY aspirations into professional-grade results.

Innovative Project Ideas to Maximize Your CNC Plasma Table Experience

CNC plasma tables have transformed the landscape of metalworking by enabling hobbyists and professionals alike to bring their creative visions to life with precision and ease. With an array of innovative project ideas, users can fully harness their CNC plasma table's capabilities. Whether you are crafting unique art pieces or designing custom components for machines, the versatility of these kits allows for a wide range of creative expressions.

CNC plasma tables have transformed the landscape of metalworking by enabling hobbyists and professionals alike to bring their creative visions to life with precision and ease. With an array of innovative project ideas, users can fully harness their CNC plasma table's capabilities. Whether you are crafting unique art pieces or designing custom components for machines, the versatility of these kits allows for a wide range of creative expressions.

One exciting project idea is to create personalized home decor. From intricately designed wall art to functional items like brackets and shelves, the possibilities are endless. Additionally, users can explore creating personalized signage for businesses or events, which can be an excellent way to combine art with practicality. Beyond decorative pieces, CNC plasma tables also enable metalworkers to venture into custom tool-making, crafting specialized tools or parts that perfectly fit their needs, thus enhancing not only their projects but also their overall metalworking experience.

Tips for Maintenance and Optimization of Your CNC Plasma Table

Maintaining and optimizing your CNC plasma table is essential for ensuring longevity and peak performance in your metalworking projects. Regular maintenance can significantly enhance the quality of your cuts and the efficiency of the machine. According to a report from the Fabricators & Manufacturers Association (FMA), proper CNC machinery care can increase productivity by up to 30% and decrease downtime by up to 25%. Simple steps such as cleaning the cutting area, checking the torch for wear, and ensuring the proper calibration of the table can make a noticeable difference in your operational workflow.

Tips for maintenance include regularly inspecting the consumables like electrodes and nozzles, as they play a crucial role in the quality of the cut. It’s advisable to replace these parts based on the manufacturer’s recommendations or sooner if you notice any inconsistencies in cuts. Additionally, optimizing your plasma table can be achieved by adjusting settings specific to the material you are working with, such as speed and voltage, to ensure the best results. Investing time in these practices not only maximizes the capabilities of your CNC plasma table but also extends its lifespan, enabling you to unlock your full creative potential in metalworking.

Related Posts

-

Unlocking Precision Cutting with the Best Cnc Plasma Table Specifications and Usage Guide

-

Challenges When Choosing the Right Best Cnc Plasma Table for Your Business Needs

-

Unlocking Precision: Technical Insights and User Guide for CNC Plasma Cutting Tables

-

Elevate Your Manufacturing with Plasma CNC Machines at the 137th Canton Fair: Insights from Global Buyers

-

Resilient Growth of Chinese Manufacturers in the Face of US China Tariffs and the Rise of Best Small CNC Plasma Cutters

-

Finding the Right Supplier for Best Plasma Table Kit and Effective Strategies for Success